Article Summary

A high-performance 3L hunting jacket is more than just rain gear; it's a technical ecosystem. This guide breaks down the critical components of a true 3L garment, from the science behind its three distinct layers to the essential manufacturing details like seam sealing and fabric selection. Understand what truly defines a top-tier hunting jacket and how these elements impact field performance, durability, and your brand's reputation.

Understanding the Core Technology

In the world of technical outdoor apparel, the "3-Layer" or "3L" designation represents the pinnacle of waterproof, breathable, and durable construction. Unlike simpler 2-layer or 2.5-layer jackets, a 3L garment is a single, robust fabric created by laminating three distinct materials together. This unified construction eliminates movement between layers, significantly enhancing durability and reducing weight. For a hunter, this means superior protection without the bulk or noise of lesser garments.

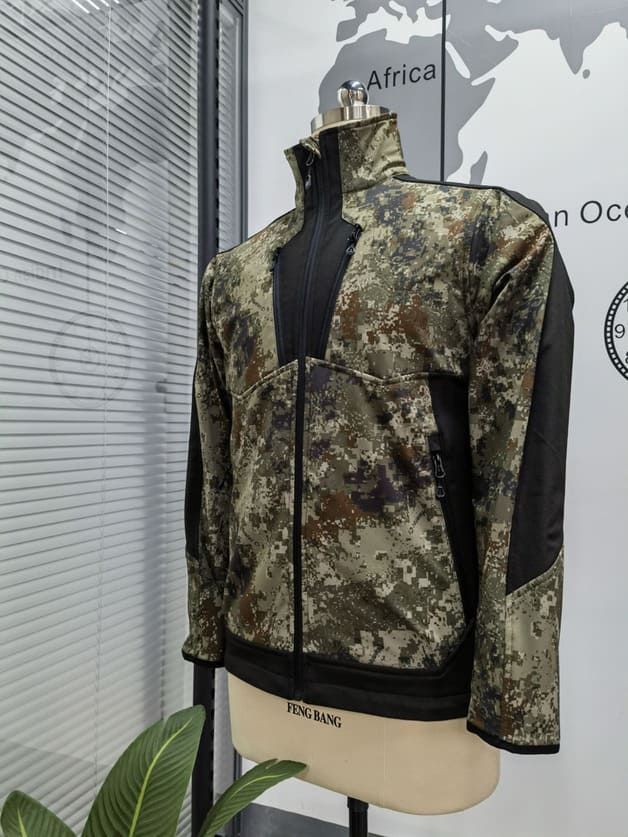

The Anatomy of a 3L Hunting Jacket

The magic of a 3L jacket lies in how its three components work in synergy. As developers, we focus on perfecting the balance between these layers to achieve optimal performance for your brand.

Layer 1: The Outer Layer (Face Fabric)

This is the jacket's first line of defense. It's not the waterproof layer itself, but it's crucial for protecting the delicate membrane beneath it. For hunting apparel, we select face fabrics that are not only abrasion-resistant but also quiet (low-noise) to avoid startling game. A durable water-repellent (DWR) finish is applied to this layer, causing water to bead up and roll off, which prevents the fabric from becoming saturated and maintains breathability.

Layer 2: The Middle Layer (The Waterproof/Breathable Membrane)

This is the heart of the jacket. It's a micro-porous membrane (like ePTFE) with billions of pores per square inch. These pores are small enough to block liquid water droplets from entering, yet large enough to allow water vapor (sweat) to escape. This is what allows a jacket to be fully waterproof while still being comfortable during strenuous activity. The quality and specification of this membrane (e.g., 20,000mm waterproof rating) is a key differentiator in performance.

Layer 3: The Inner Layer (The Backer)

This is a protective liner laminated to the inside of the membrane. Its job is to protect the membrane from body oils, sweat, and abrasion from the inside. A smooth, comfortable backer also allows the jacket to slide easily over mid-layers and feel comfortable against the skin. The type of backer can influence the jacket's overall feel, from crisp and durable to soft and quiet.

Key Manufacturing Details That Define Excellence

A great design is only as good as its execution. At Hi-nect, we focus on the critical manufacturing details that elevate a jacket from good to exceptional.

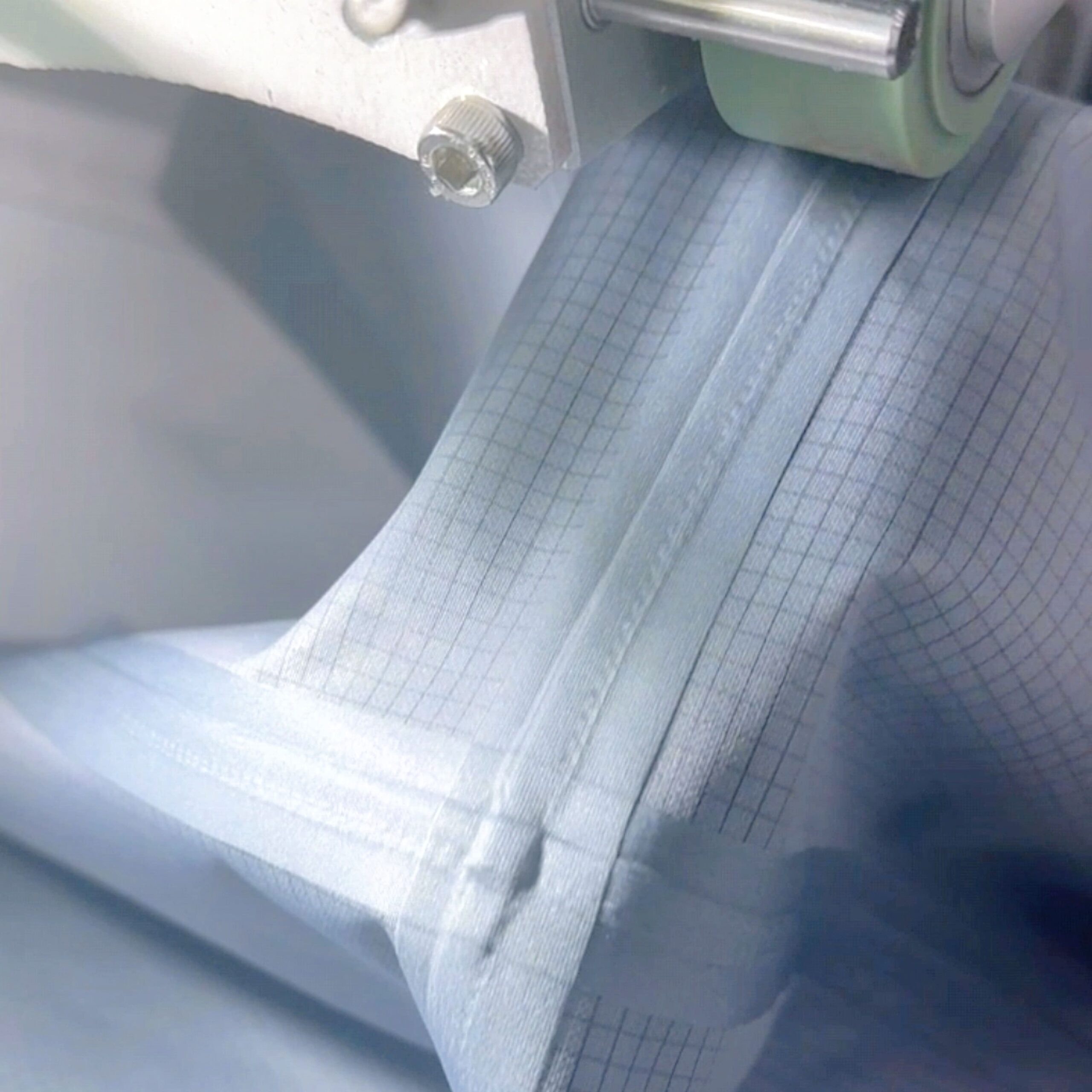

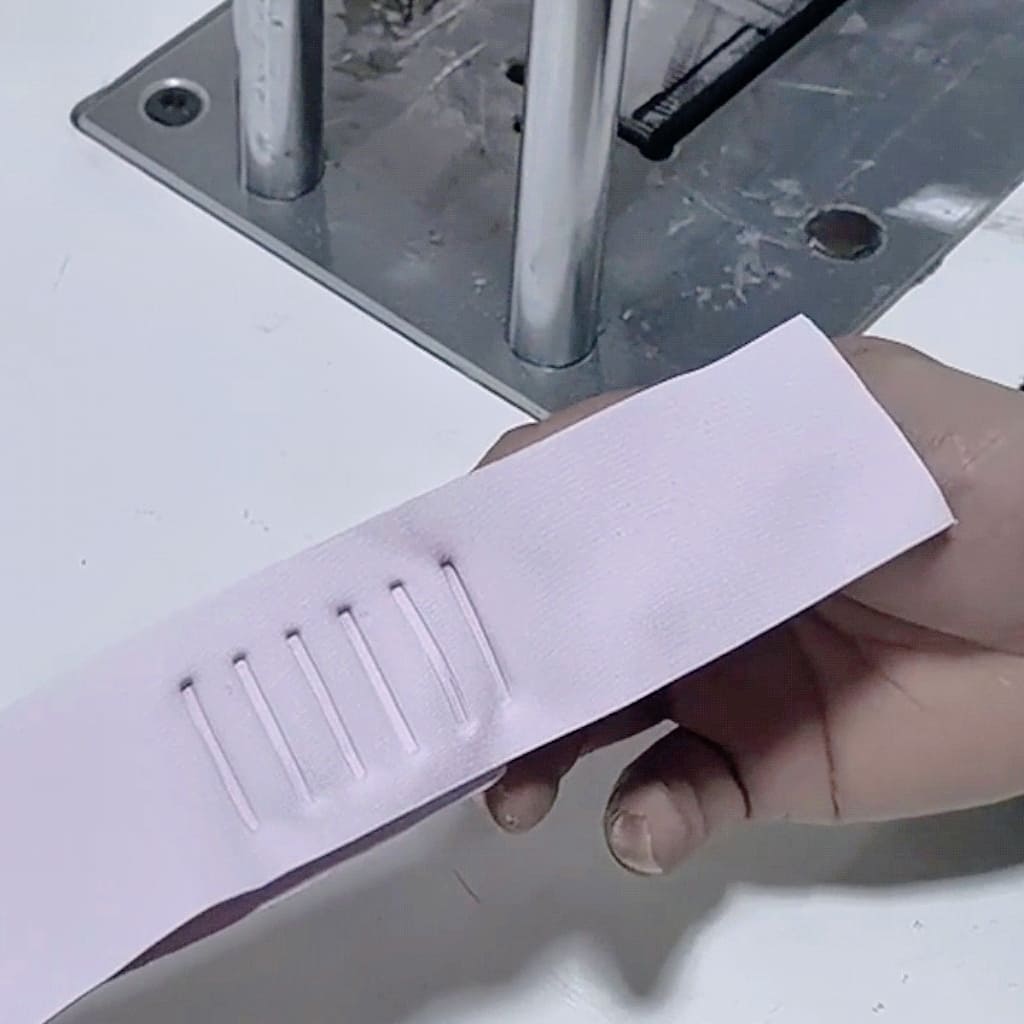

Seam Sealing is Non-Negotiable

Every stitch creates thousands of tiny holes for water to penetrate. True waterproof performance is only achieved when every single seam is meticulously cleaned and covered with a waterproof tape using specialized heat and pressure. This process, known as seam sealing, ensures the garment is a completely sealed, weatherproof fortress.

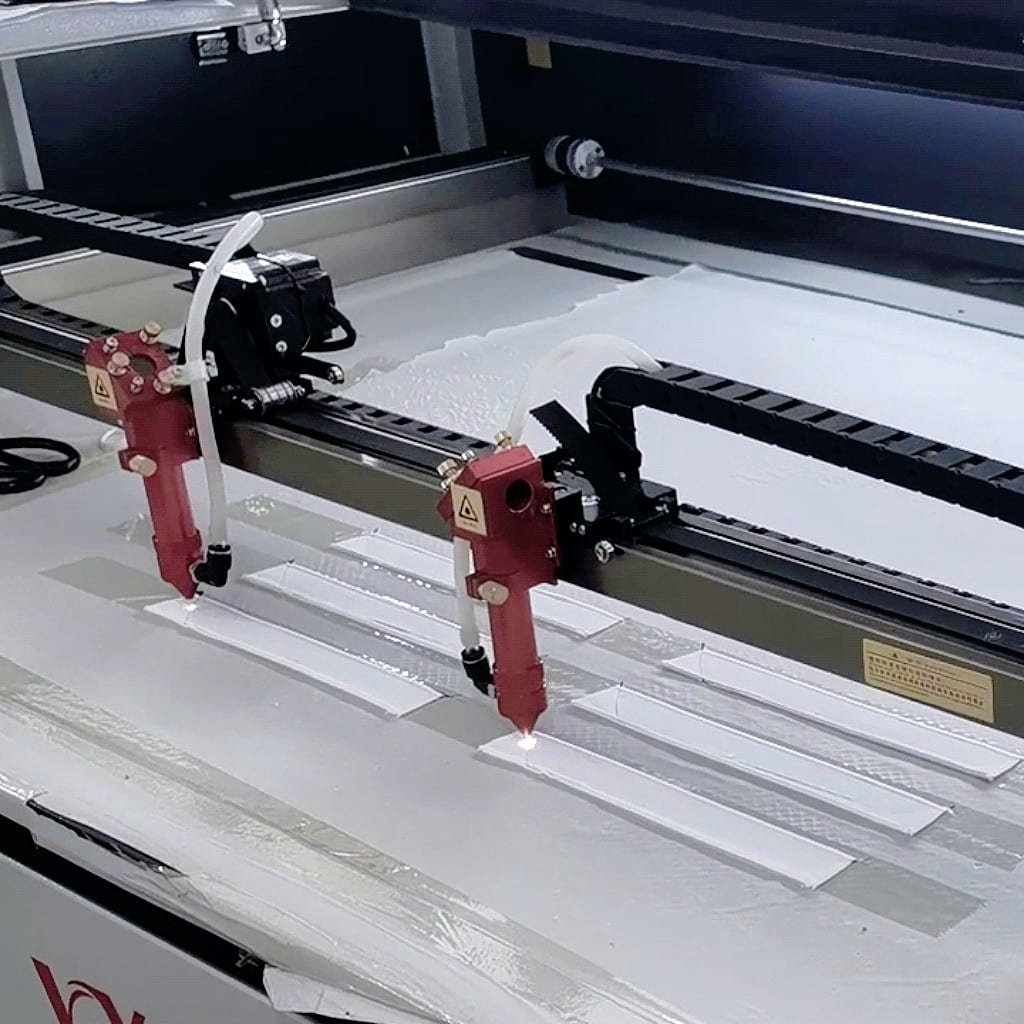

The Importance of Fit and Articulation

A hunting jacket must allow for a full range of motion—drawing a bow, shouldering a rifle, or navigating difficult terrain. We achieve this through articulated patterning, which involves designing pre-curved sleeves and shaped panels that mimic the body's natural movements. This prevents the jacket from pulling or bunching, ensuring comfort and stealth in the field.