Article Summary

The modern fleece jacket is a testament to material innovation. This guide explains how combining traditional fleece with advanced technical fabrics, like air layer materials, creates a superior garment. Learn how this hybrid approach enhances style, comfort, and performance.

Introduction: The New Generation of Fleece

The humble fleece jacket has been a reliable outdoor staple for decades. However, the most innovative brands are now pushing its boundaries. The new generation of fleece is not just about warmth; it's about intelligent design, sophisticated aesthetics, and enhanced functionality through the thoughtful combination of materials.

Why Combine Fleece with Other Fabrics?

While fleece is fantastic for warmth and breathability, it has limitations. It can be prone to pilling and lacks the structured, clean look of woven fabrics. By strategically adding panels of a different material, we can overcome these limitations and create a "best of both worlds" garment.

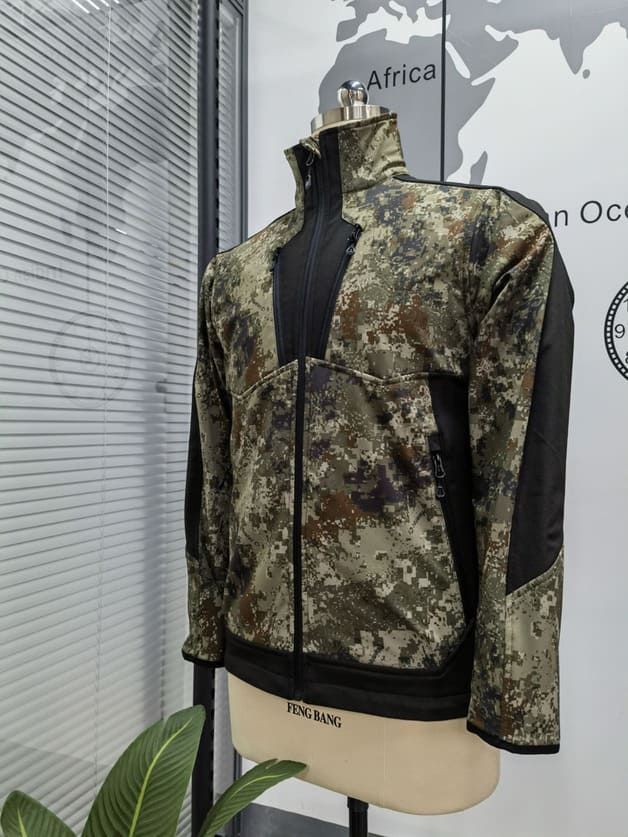

Benefit 1: Enhanced Aesthetics & Structure

This is the most noticeable benefit of a hybrid fleece like this one. Using a smooth, structured fabric like an air layer on the shoulders and chest instantly creates a more refined and premium look. It breaks up the uniform texture of the fleece, adds clean lines, and gives the jacket a sharp silhouette that traditional fleece cannot achieve. It resists wrinkles and maintains its shape, looking less like casual wear and more like a piece of technical equipment.

Benefit 2: Increased Durability in Key Zones

While the primary goal of the air layer fabric is aesthetic, it also adds a layer of durability. The smooth face of the fabric naturally resists abrasion better than the open fibers of fleece, making the shoulders more resilient to wear from backpack straps over time.

Benefit 3: Weather Resistance Where It Counts

The densely woven surface of the air layer panels offers a degree of increased wind and light moisture resistance on the upper body and hood—the areas most exposed to the elements. This adds a small but significant boost in protection without sacrificing the overall breathability of the garment.

The Result: A More Versatile, Higher-Value Product

By moving beyond a single-material design, we create a fleece jacket that appeals to a more discerning customer. It's a garment that performs excellently on the trail but also looks sharp and modern in a casual urban setting. This versatility adds significant value and broadens the appeal of your product line, positioning your brand as a leader in both performance and style.