Article Summary

Staying warm isn't about wearing one thick jacket; it's about creating a versatile system. This guide explains the classic three-part layering system and dives deep into the role of the insulated mid-layer—the true engine of warmth. Learn how to advise your customers on building a system that adapts to any weather.

Introduction: The 3-Layer System Explained

The most effective way to dress for the outdoors is not with a single, bulky garment, but with a series of layers that work together. This system allows you to adapt to changing weather conditions and activity levels by adding or removing layers. It consists of three distinct parts: a base layer, a mid-layer, and a shell layer.

The Role of Each Layer

Base Layer: The Moisture Manager

This is the layer worn next to your skin. Its primary job is not to keep you warm, but to pull moisture (sweat) away from your body to keep you dry. A dry body is a warm body. This is typically made of materials like merino wool or synthetic polyesters.

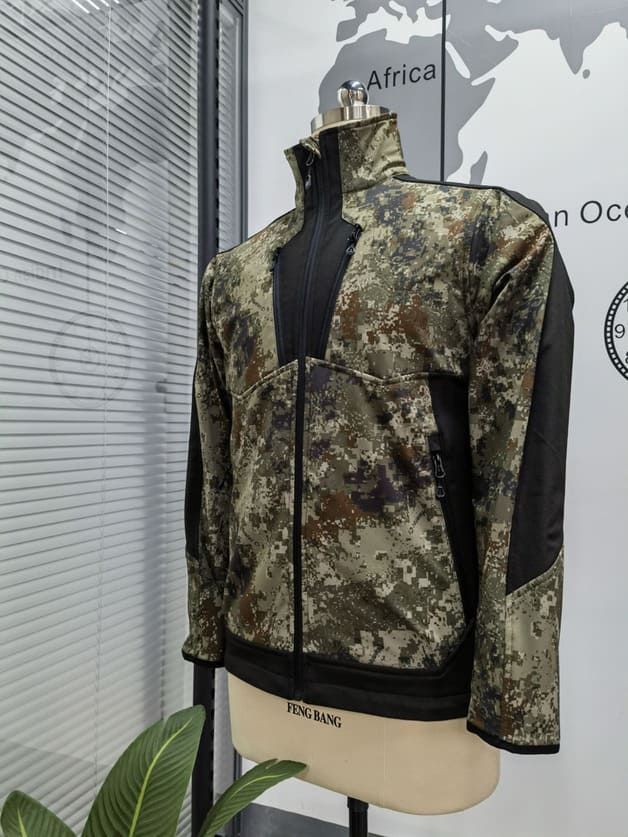

Mid-Layer: The Engine of Warmth

This is where our insulated jacket fits in. The mid-layer's sole purpose is to trap the heat your body generates and keep it close to you. Insulated jackets are perfect for this because their lofted fill creates thousands of tiny air pockets, and trapped air is an excellent insulator. The key is to provide maximum warmth for minimum weight and bulk.

Shell Layer: The Weather Shield

The outermost layer protects you from the elements—wind, rain, and snow. It's your hardshell or waterproof jacket. It works in tandem with the other layers, protecting your insulating mid-layer from getting wet, which would compromise its ability to keep you warm.

Why Synthetic Insulation Excels as a Mid-Layer

While down is an excellent insulator, modern synthetic fills (like the ones we use) offer a critical advantage for active use: performance when damp. If moisture gets into the system, synthetic insulation continues to provide significant warmth, whereas down can clump and lose its loft. This makes synthetic mid-layers a more reliable and versatile choice for hunting and other demanding outdoor activities.

Conclusion: Building a Versatile System for Your Brand

By offering a high-performance insulated mid-layer, you provide your customers with the most critical component of their outdoor apparel system. It's the piece that provides life-sustaining warmth, allowing them to stay out longer and perform better. At Hi-nect, we specialize in engineering these thermal engines to be lightweight, durable, and perfectly suited for the demands of the field.