Material Science for Hunters: A Deep Dive into Waterproof & Breathable Fabrics

By Hebe Lin, Founder of Hi-nect

My name is Hebe Lin, and I am the founder of Hi-nect. For well over a decade, my life and career have been centered on a singular obsession: deconstructing the intricate science behind high-performance outdoor apparel and translating it into tangible products that empower brands to succeed. I've had the privilege of walking the factory floors, collaborating with textile engineers in state-of-the-art labs, and, most importantly, listening to the deeply specific needs of brand founders and product managers across Europe and North America.

One truth has become profoundly clear: the term "waterproof breathable" is perhaps the most overused and least understood phrase in our industry. For the mass market, it’s a simple checkbox feature. But for you, the leader of a serious hunting or outdoor brand, it is the absolute bedrock of your product's integrity and your customer's trust. Getting it right is not just a technical challenge; it is a strategic imperative.

This guide is the culmination of my experience. I am writing this for you—the brand founder mapping out your five-year product roadmap, the product manager agonizing over spec sheets, the sourcing director weighing the complex trade-offs between performance, cost, and brand story.

My goal is to move beyond marketing jargon and empower you with the foundational knowledge to build a truly superior product line. We won't just scratch the surface. We will go deep into the physics, the polymers, the manufacturing processes, and the strategic decisions that Hi-nect and our partners navigate every single day. This is the conversation I have with my most valued clients, and I want to share it with you. Let’s begin.

The Hunter's Dilemma: Battling Water from Two Fronts

Before we can appreciate the technology, we must first respect the problem it's designed to solve. A hunter in the field is fighting a war on two fronts. From the outside, there is environmental moisture: rain, snow, sleet, and even heavy fog. The obvious goal is to create an impenetrable barrier to keep this water out. This is the "waterproof" part of the equation.

But the second front, and often the more insidious one, is the battle from within. The active hunter generates a significant amount of heat and perspiration. An average person can produce over a liter of sweat per hour during strenuous activity. If this moisture vapor cannot escape, it will condense on the inside of the garment, leaving the wearer just as wet as if they had stood in the rain without a jacket.

This phenomenon, known as "wetting out from the inside," is not just uncomfortable; it's dangerous. Wet clothing loses its insulating properties, leading to rapid heat loss and increasing the risk of hypothermia, even in moderate conditions.

This is the core paradox: a material must be porous enough to let tiny water vapor molecules escape, yet non-porous enough to block much larger liquid water droplets from entering. Solving this elegantly and durably is the holy grail of performance fabrics.

Deconstructing the Numbers: A Guide to Technical Specifications

To move beyond vague claims like "highly waterproof," you must learn to speak the language of the lab. Technical specifications are the objective measures of a fabric's performance. Understanding them allows you to make informed, data-driven decisions.

What is "Waterproof"? The Hydrostatic Head (HH) Rating

The most common measure of a fabric's water resistance is its Hydrostatic Head (HH) rating, typically measured in millimeters (mm). This test measures the height of a column of water that can be placed on the surface of the fabric before the first drop penetrates.

- How to Visualize It: Imagine a tall, vertical tube placed on the fabric. The higher you can fill that tube with water before the fabric leaks, the higher the HH rating. A 10,000mm rating means the fabric can withstand the pressure of a 10-meter-tall column of water.

- What the Numbers Mean in the Real World:

- 5,000mm: Suitable for light rain and dry snow. It may fail under sustained pressure, such as kneeling on wet ground.

- 10,000mm - 15,000mm: A solid benchmark for all-around hunting apparel that can handle moderate to heavy rain and snow. [11][16]

- 20,000 g/m²/24h and above: Excellent breathability for high-exertion activities. [9]

Resistance to Evaporative Heat Transfer (RET):

- What it is: RET tests how much resistance a fabric presents to water vapor. Unlike MVTR, a lower RET number is better.

- General Guide:

- RET 0-6: Extremely breathable.

- RET 6-13: Very breathable, a common range for high-quality gear.

- RET 13-20: Breathable.

- RET 20+: Slightly breathable to not breathable.

The Strategic Choice: A garment for a stationary hunter might prioritize a very high HH rating. A garment for an active mountain hunter must prioritize an excellent MVTR or low RET score.

The Invisible Shield: Durable Water Repellency (DWR)

I cannot overstate the importance of DWR. It is the invisible technology that makes your waterproof garments function as intended.

- How it Works: DWR is a polymer-based finish applied to the outer fabric that causes water to bead up and roll off.

- The Evolution and Environmental Challenge:

- C8 (Long-Chain): The old standard, highly effective but phased out due to environmental and health concerns.

- C6 (Short-Chain): The current common and reliable choice, offering good performance with a much better environmental profile.

- PFC-Free: The most environmentally friendly option, but performance, especially resistance to oils, can be a challenge.

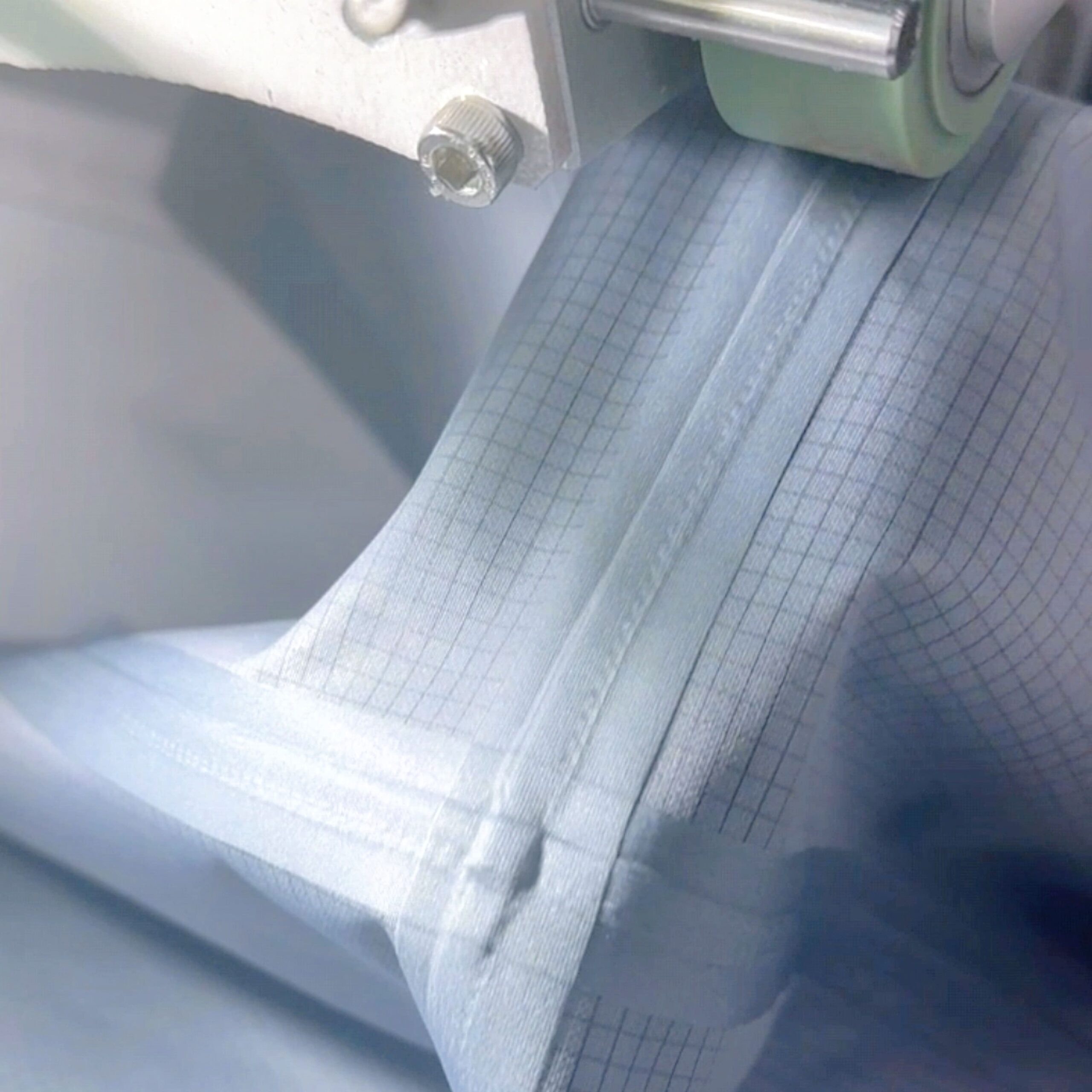

The Manufacturer's Role: This is where a partnership with an experienced manufacturer becomes critical. We help you select the right chemistry based on your brand's positioning and ensure it is applied with precision for maximum longevity.

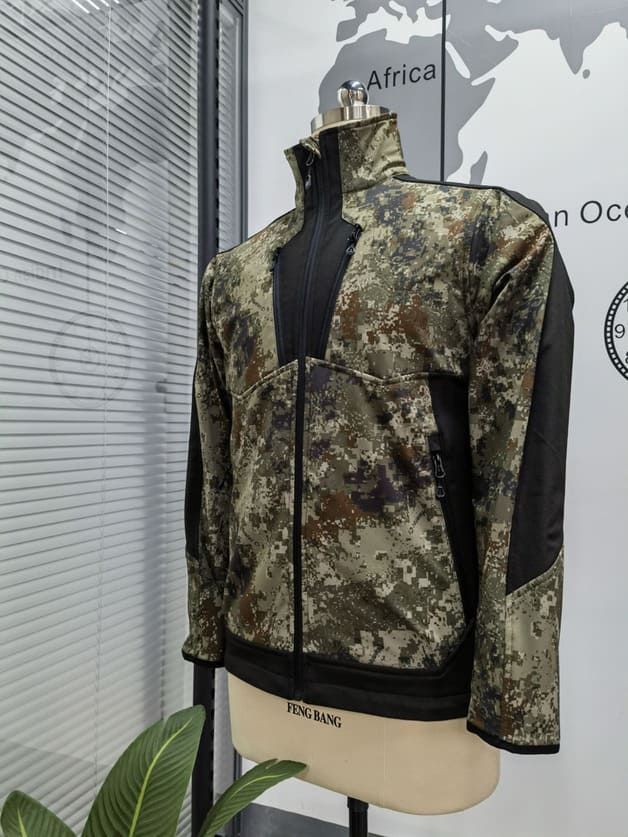

The Architecture of Protection: A Guide to Fabric Constructions

The construction method—2-Layer, 2.5-Layer, or 3-Layer—is a fundamental decision impacting durability, weight, cost, and feel.

The Workhorse: 2-Layer (2L) Construction

- Structure: A membrane is bonded to the outer face fabric. A separate, loose-hanging liner is required inside to protect the membrane.

- Pros: Cost-effective, supple, and quiet.

- Cons: Heavier, bulkier, and less durable than 3L.

- Best Use Cases: Insulated parkas, entry-level rain gear, and lifestyle pieces.

The Specialist: 2.5-Layer (2.5L) Construction

- Structure: A membrane is bonded to a face fabric, and a thin protective print or coating (the "half layer") is applied to the inside.

- Pros: Extremely lightweight and packable.

- Cons: Can feel clammy against the skin and is less durable than 3L.

- Best Use Cases: Emergency rain shells where space and weight are top priorities.

The Pinnacle: 3-Layer (3L) Construction

- Structure: The membrane is laminated between an outer face fabric and an inner fabric backer, creating a single, robust textile.

- Pros: Maximum durability, highest performance, and lighter than 2L.

- Cons: Most expensive and can feel stiffer than other constructions.

- Best Use Cases: Flagship products, hardshell jackets and pants, and any gear where reliability and performance are non-negotiable.

The Role of Backers in 3L Fabrics: The type of inner backer used has a huge impact. A standard tricot backer is durable, while a brushed backer is quieter and adds slight insulation. Newer technologies create backers that are significantly softer, lighter, and more breathable.

Conclusion: Your Fabric Is Your Brand's Promise

We have covered a tremendous amount of technical ground. If there is one thing I want you to take away from this, it is this: your fabric choice is a direct reflection of the promise you make to your customer.

A 10,000mm, 2.5L shell makes a promise of lightweight protection. A 20,000mm, 3L hardshell makes a promise of absolute reliability in the harshest conditions. Both can be excellent products, but they fulfill different promises.

My role, and the role of my team at Hi-nect, is to be your strategic partner in this process. We are not simply order-takers; we are technical consultants. We immerse ourselves in your brand's DNA, analyze your target user, and help you navigate these complex choices. We leverage our deep relationships with the world’s best textile mills to source the perfect materials or develop a completely custom fabric unique to your brand.

Building exceptional hunting apparel is a complex synthesis of science, craftsmanship, and a deep understanding of the end-user. The fabric is the foundation upon which everything else is built. I hope this guide has given you a clearer framework for making these critical decisions.

Thank you for your time.

Hebe Lin.