Who Really Makes the Best Hunting Clothes?

By Hebe Lin, Founder of Hi-nect

As the founder of a company that lives and breathes technical outdoor apparel, the question, "What company makes the best hunting clothes?" is one I encounter frequently. It's a question often posed by end-users on forums and in product reviews. But more importantly, it's a question that silently guides the decisions of every brand founder, product manager, and purchasing director I partner with. They aren't just asking for a name; they are asking for a benchmark, a formula for success in a market saturated with claims of superiority.

The simple answer, the one you might find in a magazine's gear guide, is a list of respected brands. Brands like Sitka, KUIU, or the American-made Forloh have rightfully earned their reputations through relentless marketing, community building, and, of course, solid product offerings. But that's a B2C answer to a B2B problem. The real, more strategic answer is that the "best" hunting clothes are not made by a single company, but forged in a collaborative crucible between a visionary brand and an expert manufacturing partner.

The logo on the chest is the promise; the science, materials, and craftsmanship embedded in the seams are what deliver on that promise. For brand leaders, the critical question isn't "Who is the best?" but rather, "How do we build the best, and who can we trust to build it with us?"

In this analysis, I will pull back the curtain on the manufacturing side of the industry. We will move beyond brand names and deconstruct the very essence of what elevates a piece of hunting apparel from "good enough" to "best in class." We will explore the synergy of materials, construction, and design, and finally, I will outline a strategic framework for choosing a manufacturing partner who can not only execute your vision but elevate it.

Deconstructing "The Best": Beyond the Brand Tag and into the Technical Weave

What does "best" truly mean when you're glassing a ridgeline in a freezing gale or stalking through dense, wet undergrowth? It's not about fashion. It's a quantifiable equation of performance, durability, and physiological comfort. It's a system designed for a purpose. Any brand aiming for the top of the pyramid must master three fundamental pillars: Material Science, Construction Integrity, and Ergonomic Design. The "best" brands are those that understand these pillars are inseparable and depend entirely on the capabilities of their manufacturing partner.

The Material Science Revolution: The Fabric of Success

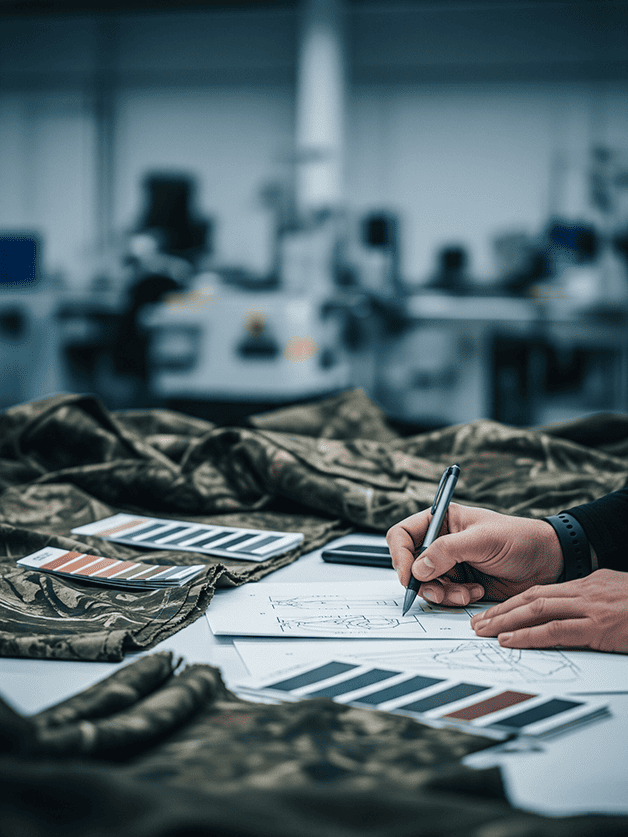

The foundation of any elite garment is the material itself. A decade ago, choices were limited. Today, we are in a golden age of textile innovation. However, navigating this landscape requires deep expertise. A great brand doesn't just pick a fabric from a catalog; they understand its properties and how they align with the end-user's needs. A true manufacturing partner facilitates this by co-developing or sourcing the perfect solution.

Membranes and Laminates: The Heart of Weatherproofness

The core of any serious hard shell is the waterproof-breathable (WPB) membrane. While Gore-Tex® remains a household name, the market is rich with powerful alternatives like eVent®, Pertex® Shield, and a host of proprietary ePTFE and hydrophilic PU membranes that we work with. The "best" choice isn't universal; it's specific to the application.

- Air-Permeable vs. Hydrophilic: An air-permeable ePTFE membrane (like eVent®) offers superior breathability from the moment you put it on, making it ideal for high-exertion activities. A monolithic hydrophilic PU membrane, on the other hand, can offer greater durability and resistance to contamination from oils and dirt.

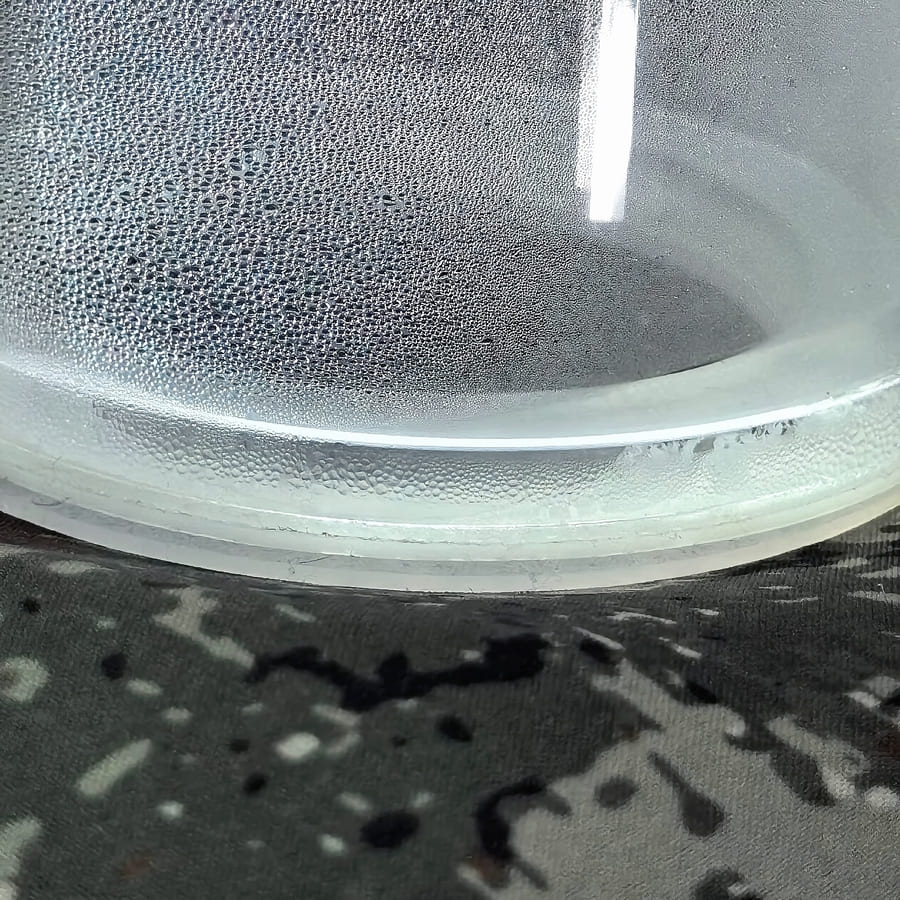

- The Lamination Process: The membrane is useless without flawless lamination. This is where a manufacturer's expertise is non-negotiable. At Hi-nect, our X-Joy™ R&D studio obsesses over the details: the specific adhesive used, the precise heat and pressure applied, and the curing times. A poorly executed lamination can lead to delamination (the layers separating) after just a few seasons of hard use, instantly destroying a brand's reputation. We see our role as the guardian of that long-term performance. We ensure the face fabric, membrane, and tricot backer are bonded into a single, durable, high-performance entity.

Face Fabrics and DWR: The First Line of Defense

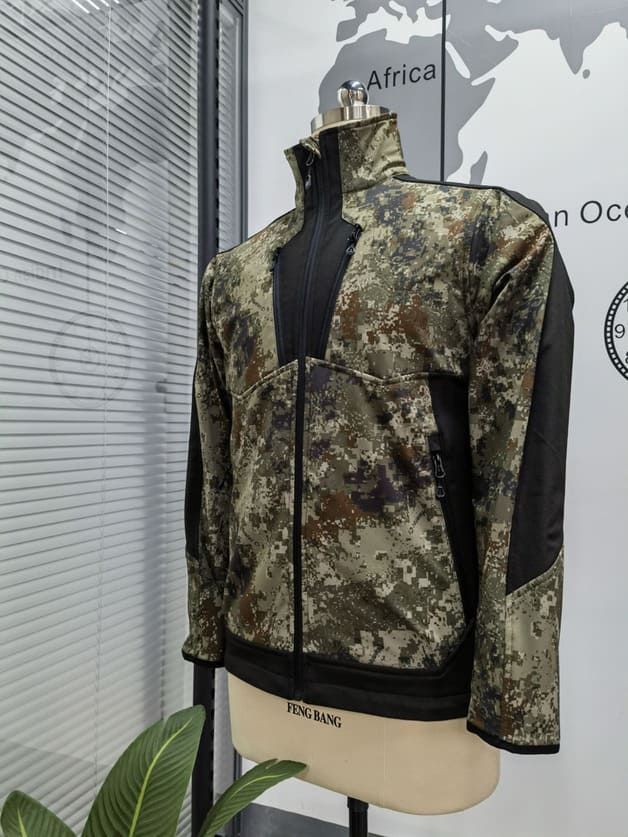

The outer fabric does more than just carry the camouflage pattern. It must be quiet, durable, and effectively shed water. The choice of yarn (e.g., Cordura® nylon for abrasion resistance, polyester for colorfastness and hydrophobia) and weave (ripstop for tear strength, plain weave for quietness) is a critical decision.

The Durable Water Repellent (DWR) finish is equally vital. While C8 fluorocarbons offered incredible performance, the industry is rightly moving towards more environmentally friendly C6 or C0 (PFC-free) options. The challenge is that these options often have lower durability. An expert manufacturer mitigates this through superior application techniques and by sourcing next-generation PFC-free DWRs that offer renewed performance, ensuring a brand can be both responsible and high-performing.

Insulation: The Science of Warmth Without Weight

The conversation has moved far beyond generic "puffy" jackets. Today's leading brands use body-mapping, placing insulation strategically.

- Down vs. Synthetic: Hydrophobic down offers the best warmth-to-weight ratio, but high-performance synthetics like Primaloft® Gold or Climashield® APEX excel in damp conditions, retaining insulating value when wet.

- Active Insulation: The real frontier is "active insulation." Materials like Polartec® Alpha® or Primaloft® Active are designed to be worn during exertion, dumping excess heat and moisture while still providing warmth. Integrating these materials into a hybrid garment requires advanced construction knowledge to manage airflow and seam interfaces. This is where a simple assembly factory fails and a true technical partner thrives.

The Art of Construction: Where Vision Becomes Reality

A brilliant design with world-class materials can be utterly ruined by poor construction. This is the factory floor, where millimeters matter and consistency is king. This is where the "best" is separated from the rest.

Seam Integrity: The Unsung Hero

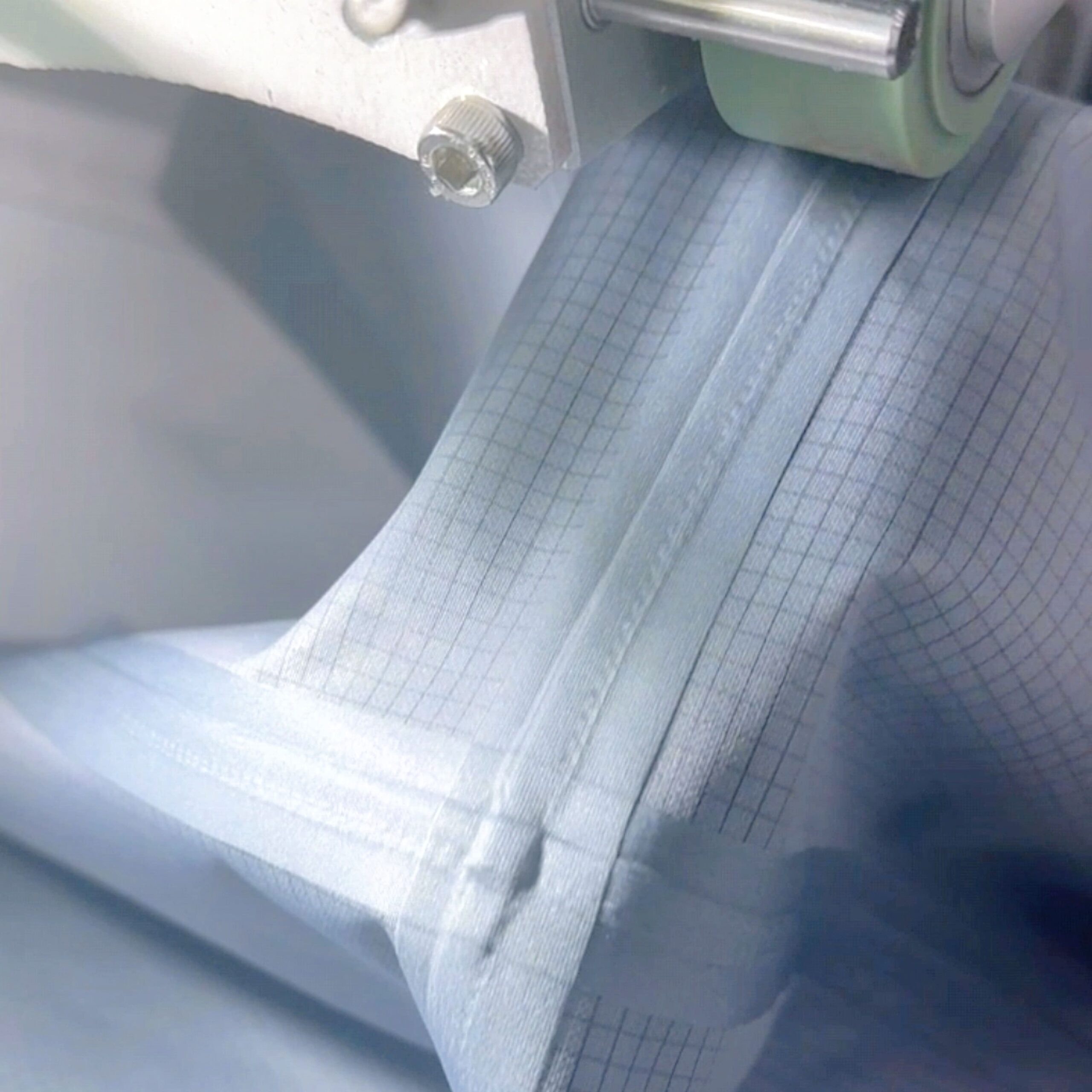

A garment is only as waterproof as its weakest point, which is almost always a seam.

- Seam Taping: Applying seam tape over stitched seams is an art form. The tape width, adhesive type, and application temperature must be perfectly matched to the fabric. We use precision machinery that regulates heat and pressure to create a bond that is as strong and waterproof as the fabric itself. We often see products from other factories where the tape peels after minimal use—a fatal flaw.

- Welded Seams: For the ultimate in low-profile, waterproof construction, radio-frequency (RF) or ultrasonic welding can be used to bond fabrics without stitching. This is a highly technical process requiring specialized equipment and operators. It reduces bulk and eliminates potential leak points, but it's a capability only a small fraction of manufacturers possess. It's a hallmark of a truly premium product.

Zippers and Hardware: The Critical Touchpoints

A failed zipper can render a $700 jacket useless. We exclusively use top-tier hardware from YKK®, ensuring reliability. But it goes further. We guide our partners on choosing the right type: AquaGuard® zippers for weather resistance, coil zippers for flexibility in pockets, or Vislon® zippers for durability in high-cycle areas. The zipper garage, the small flap at the top, is a detail we never miss, preventing chin chafe and providing a clean finish. These small details collectively build a user's confidence in the brand.

Micro-Details: The 1% That Makes 100% of the Difference

Look at the cuff of a premium jacket. Is it a simple elastic band, or an articulated, laser-cut, bonded cuff with a custom tab? How is the hood designed? Does it have a 3-way adjustment system that allows it to move with the user's head without obscuring peripheral vision? Is the hem drawcord managed to prevent snagging on branches? These are not accidents. They are the result of a deep, iterative design and prototyping process between the brand and a manufacturer who understands the nuances of field use.

The Human Factor: Ergonomics and Field-Tested Design

The final piece of the puzzle is how the garment fits and moves on a human body in dynamic, real-world situations.

Articulated Patterning: Designing for Movement

A hunter is not a static mannequin. They climb, crawl, draw a bow, and shoulder a rifle. The "best" apparel anticipates these movements. Articulated patterning involves adding extra shape and panels to key areas like the elbows and knees, and using gussets in the underarms and crotch. This prevents the garment from pulling, binding, or riding up. Creating these complex patterns requires skilled pattern makers and a deep understanding of biomechanics—a core competency of our R&D team.

The System Approach

Leading brands no longer sell individual pieces; they sell a layering system. A base layer, a mid-layer, and an outer shell must all be designed to work together. The fit must be synergistic, so layers don't bunch up. Features must be aligned; for example, the chest pocket zippers on a mid-layer should be accessible through the pit-zips of the shell. This level of integrated design requires a holistic view that only a true partner, involved from the concept stage, can help facilitate.

The Strategic Partnership: Choosing Your Manufacturer in 2025 and Beyond

Understanding what makes the best gear is only half the battle. The other half is finding the right partner to build it. The traditional OEM/ODM model is often transactional and fraught with challenges for ambitious brands, especially those that are new or medium-sized.

Common Pain Points with Traditional Suppliers:

- Prohibitive MOQs (Minimum Order Quantities): Many large factories demand 1,000 or even 3,000 pieces per style/color. This is untenable for a startup testing a new design or a brand wanting to offer a wider, more specialized range. It kills innovation and drains cash flow.

- Lack of R&D Input: Most factories are built for execution, not innovation. They will build exactly what you specify, even if they see a flaw. They lack the R&D culture to challenge a design, suggest a better material, or co-develop a solution to a complex problem.

- Communication and Cultural Barriers: Misunderstandings about technical details, delays in communication, and a lack of transparency can derail a production timeline and lead to costly errors.

- Inconsistent Quality: A perfect "golden sample" is often followed by a production run with significant deviations. This stems from a lack of robust, systematic quality control processes embedded throughout the entire production line.

To build the "best," you need to transcend this outdated model. You need a partner, not just a supplier. Here’s what to look for:

The Modern Manufacturing Partner Checklist:

- A Dedicated R&D Engine: Look for a partner with an in-house R&D team like our X-Joy™ studio. This is a team whose job is to solve problems, test new materials, and perfect construction techniques before they hit the main production floor. They should be your collaborative design and engineering resource.

- Flexible, Strategic MOQs: A forward-thinking partner understands the needs of a growing brand. At Hi-nect, our ability to start with as few as 200 pieces is a strategic decision. It empowers our clients to be more agile, test the market with less risk, and invest their capital in growth rather than excess inventory.

- Verifiable Quality and Compliance Systems: Don't just take their word for it. Look for internationally recognized certifications like BSCI (Business Social Compliance Initiative), which demonstrates a commitment to ethical working conditions. Ask for a detailed breakdown of their QC process. Our process, for example, includes incoming material inspection, in-line checks at critical assembly stages, and a final 100% inspection of every single garment. This is the European standard our high-end clients expect.

- Transparent and Proactive Communication: Your partner should feel like an extension of your own team. They should provide clear timelines, flag potential issues early, and be fluent in the technical language of performance apparel.

Conclusion: The Partner is the Platform

So, what company makes the best hunting clothes? The answer is you, the brand. It’s your vision, your understanding of the customer, and your story.

But the silent, indispensable partner in that success is the manufacturer who brings that vision to life with technical excellence, unwavering quality, and collaborative spirit. The "best" apparel is a direct reflection of the quality of that partnership.

When you evaluate your supply chain, don't just ask for a price list. Ask about R&D capabilities. Challenge them on their QC process. Discuss their approach to material innovation. Inquire about their flexibility.

The path to creating the best hunting clothes on the market is not about finding the cheapest supplier. It's about finding the most capable and reliable partner who provides the platform upon which your brand can build its legacy.