Lowering MOQs: A Guide for Hunting & Outdoor Brands

📌 Table of Contents

You’ve done it. After countless late nights, sketches on napkins, and heated debates over fabric textures, you’ve perfected the design for a piece of hunting gear that you know, deep in your gut, is a game-changer. It’s a jacket that moves with the body like a second skin, a pack that anticipates a hunter’s every need, a base layer that finally solves the puzzle of warmth and breathability. The vision is crystal clear. You’ve built your brand story, you know your customer avatar by name, and you are ready to make your mark on the industry.

With a surge of adrenaline, you draft an email to a potential manufacturer, attaching your beautiful design files. You’re not just sending a spec sheet; you’re sending a piece of your soul, the culmination of your passion. You hit "send" and wait, dreaming of the day the first production run lands at your warehouse.

Then, the reply arrives. Your heart pounds as you open it. You scan past the pleasantries, looking for the numbers, the quote, the timeline. And then you see it. A single, three-letter acronym followed by a number that feels like a punch to the stomach: “MOQ: 1,000 pieces per style, per color.”

Suddenly, the air goes out of the room. One thousand pieces? Per color? For a brand new, untested product? The excitement you felt moments ago is replaced by a cold wave of reality. The number represents more capital than you have, more inventory than you can store, and more risk than you can possibly stomach. It feels like the door to your dream has just been slammed shut and bolted.

This scenario is not just a story; it is the painful reality for thousands of ambitious founders of small and medium-sized outdoor brands. It is the great filter of the apparel industry, the classic catch-22 that suffocates brilliant ideas before they ever have a chance to breathe: you need to produce gear to grow your brand, but you need to be a big brand to afford to produce gear.

As the founder of Hi-nect, a manufacturing partner born from the desire to empower brands like yours, I have witnessed this struggle intimately for over fifteen years. I’ve seen the frustration in the eyes of designers and the despair in the spreadsheets of entrepreneurs. But I am here to tell you that this wall, this seemingly insurmountable barrier of the Minimum Order Quantity (MOQ), is not the end of your story. It is simply the first strategic challenge you need to master.

This is not going to be a brief overview. This is a masterclass. We are going to dismantle the concept of the MOQ piece by piece, look deep into the machinery of the global supply chain, and arm you with the knowledge, strategies, and mindset required to transform MOQs from a roadblock into a roadmap for intelligent, sustainable growth. If you are tired of feeling like the manufacturing world is designed to keep you out, then settle in. We are about to give you the keys to the factory.

Chapter 1: Deconstructing the Machine – The Unseen Economics Behind Every MOQ

Before we can strategize, we must first understand. To an outsider, an MOQ can feel arbitrary, like a number pulled from thin air designed specifically to make life difficult for the little guy. But in reality, every MOQ is a direct reflection of the complex, interwoven, and often brutal economics of global apparel manufacturing. It’s a number born from the physics of machinery, the chemistry of dyes, and the hard math of labor efficiency. By understanding the "why" behind the number, you gain the power to influence it.

Let’s pull back the curtain and walk through the factory, not as a client, but as an insider.

1.1 The Foundation: Raw Material Minimums

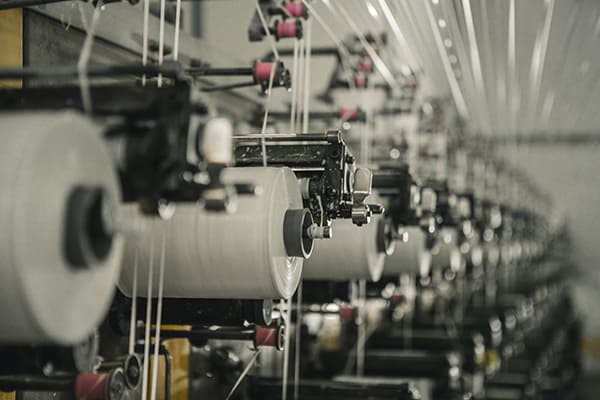

The journey of your garment doesn’t begin on our sewing floor. It begins months earlier, in the deafening roar of a textile mill, a place of massive scale where your order is a tiny drop in an ocean of production. We, your garment manufacturer, are customers of these mills, and we are subject to their MOQs.

The Yarn Spinner’s Reality:

Before fabric, there is yarn. A spinning mill takes raw fibers—be it merino wool from Australia, nylon polymers, or organic cotton—and spins them into yarn. These mills operate on colossal scales. Setting up their machinery to spin a specific type, weight, and twist of yarn is a monumental task. They might need to produce a minimum of several tons of a single type of yarn to make the run economically viable.

The Weaver’s or Knitter’s Dilemma:

That yarn is then sent to a weaving (for non-stretch fabrics like canvas or ripstop) or knitting (for stretch fabrics like fleece or jersey) facility. Imagine a loom the size of a small bus. To set this machine up to weave your specific fabric—with its unique denier, weave pattern (like ripstop or twill), and density—can take a full day of highly skilled labor. The mill simply cannot afford to do this for a 100-meter run. They typically require a minimum order of 3,000 to 5,000 meters of "greige" fabric (the raw, undyed, unfinished material) just to turn the machines on1.

The Dyer’s Cauldron:

This is often the biggest MOQ driver. Greige fabric is dyed in massive, pressurized vats. A typical "dye lot" for a custom color can range from 500 to 2,000 kilograms of fabric2. The process involves complex chemistry, precise temperatures, and huge amounts of water and energy. To dye a small batch of, say, 100kg, is incredibly wasteful and cost-prohibitive. The lab dips and color matching process alone costs hundreds of dollars. This is why a custom Pantone color for your brand’s signature "Forest Sage" green immediately triggers a high fabric MOQ. The mill needs to dye a full lot, whether you use all of it or not.

The Finisher’s Touch:

After dyeing, the fabric goes through finishing processes. This could be applying a Durable Water Repellent (DWR) coating, a lamination process to create a 3-layer waterproof-breathable membrane, or a brushing process to create fleece. Each of these stages involves yet another set of massive, expensive machinery that requires a minimum run length to be efficient.

So, when a fabric mill tells us their MOQ is 3,000 meters, that number is the result of the combined minimums of the spinner, the weaver, the dyer, and the finisher.

1.2 The World of Trims and Components

A technical hunting jacket isn’t just fabric. It’s a complex assembly of dozens of individual components, each with its own supply chain and its own MOQ. I’ve seen a $500,000 production run delayed for six weeks because of a 15-cent custom zipper pull. The "trim trap" is real.

- Zippers: A giant like YKK is a model of efficiency. To produce a specific type of zipper (e.g., a #5 Vislon AquaGuard) in a custom color requires them to set up their dyeing and molding equipment. Their MOQ for a custom color can be thousands of individual zippers, a factor that must be included in garment costing3.

- Thread: Thread is dyed in large vats, just like fabric. A custom color match from a supplier like Coats might require a minimum order of 100 large cones of thread.

- Labels and Heat Transfers: Your branded labels (both woven and printed) are produced by specialized suppliers. Setting up the loom for a custom woven label or the screen for a heat transfer has a fixed cost, making small runs very expensive per piece. They often require a minimum of 1,000 to 5,000 labels.

- Hardware: Snaps, cord locks, buttons, and buckles are often injection-molded. The steel mold for a custom-designed cord lock can cost thousands of dollars to create4. The supplier needs to produce tens of thousands of units just to recoup the cost of the mold. Even for stock hardware in a custom color, the dyeing or painting process will have a high minimum.

1.3 The Economics of the Factory Floor

Finally, we arrive at our factory, the place where all these components come together. Even if you managed to source all the materials yourself in small quantities (which is nearly impossible), our own operational economics dictate a minimum production run.

The Cost of Setup (The "Soft Costs"):

Before a single stitch is sewn, a huge amount of preparatory work happens. This setup cost is largely fixed, whether we’re making 100 pieces or 1,000.

- Pattern & Grading: Our technical team takes your tech pack and creates a master digital pattern for the sample size<sup data-citation='{"url":"https://thefashionbusinesscoach.com/blog/whatisatechpack","title":"What is a tech pack and why you need one for apparel production","content":"A tech pack is an essential blueprint for apparel production. It is a detailed document that communicates every specification—from measurements and materials to stitching details—to the manufacturer, ensuring the final product matches the designer\’s vision."}’>5. They then "grade" this pattern for every other size in your range (S, M, L, XL, etc.). This is highly skilled work.

- Marker Making: To minimize fabric waste, a computer program arranges all the pattern pieces for all the different sizes onto a giant digital layout called a "marker." This is like the world’s most complex game of Tetris.

- Spreading & Cutting: The fabric is laid out in massive stacks, sometimes hundreds of layers deep, on a long cutting table. The marker is printed and laid on top, and a high-speed cutting machine follows the lines. Setting this up is a precise, time-consuming process.

- Line Configuration: A sewing line for a technical jacket might involve 20-40 operators, each performing a specific task with a specialized machine (e.g., single needle, overlock, bar tack, seam sealing). We have to configure these machines, prepare bundles of cut pieces for each station, and train the operators on the specific, and often complex, construction of your garment. This setup can take half a day or more.

Imagine a high-end restaurant kitchen. The chefs spend hours doing "mise en place"—chopping vegetables, making sauces, preparing proteins. This is their setup. It wouldn’t make sense for them to do all that work just to cook a single plate of food. They do it to prepare for a full night of service. A sewing line is the same. The setup cost must be amortized over a sufficiently large number of units to keep the per-piece price reasonable.

The Power of Rhythm (Labor Efficiency):

Once the line is running, the operators find a rhythm. Each movement becomes muscle memory. The 20th jacket they assemble is significantly faster and often higher quality than the 1st. This is the "learning curve" of production. Small orders mean the line is constantly stopping, re-configuring, and starting a new learning curve. This inefficiency drives up the labor cost per unit dramatically.

The Factory’s Opportunity Cost:

Every production line in our facility represents a certain amount of revenue potential per day. If we dedicate a line to your 100-piece order, which might only take a few hours to complete after a lengthy setup, that line then sits idle while we set up for the next small job. We have lost the opportunity to run a 1,000-piece order that would have kept the line running efficiently all day. The MOQ ensures that we can utilize our capacity effectively and keep our business healthy.

So, when you receive that MOQ of 1,000 pieces, it’s not a personal rejection. It’s a number that represents the combined economic realities of yarn spinners, fabric weavers, dye houses, trim suppliers, and the operational efficiency of our factory floor. It’s the point at which the global supply chain can deliver a high-quality product at a price that is viable for both of us.

Chapter 2: The "MOQ Trap" – A Cautionary Tale for Growing Brands

Understanding why MOQs exist is one thing. Understanding the profound danger of agreeing to an MOQ your brand isn’t ready for is another. For a small or medium-sized brand, the pressure to "just make it work" can be immense. You might be tempted to drain your savings, take out a loan, or max out your credit cards to meet that high minimum, believing that having product—any product—is the only way forward.

This is a dangerous and often fatal mistake. I have seen promising brands with brilliant products go bankrupt, not because their ideas were bad, but because they fell into the "MOQ Trap." This trap isn’t just a single problem; it’s a series of interconnected business risks that can create a death spiral for a growing company.

2.1 The Financial Guillotine: Cash Flow & Inventory Burden

Cash is the oxygen of your business. It’s not profit, it’s not revenue—it’s the liquid capital you have on hand to pay for marketing, salaries, web hosting, and, most importantly, your next product development cycle. A high MOQ acts like a giant vacuum, sucking all the oxygen out of your business and converting it into a static, illiquid pile of inventory.

Let’s do some simple, terrifying math.

-

Scenario A: The "Dream" Order (Low MOQ)

- Your ideal starting order: 200 jackets

- Landed cost per jacket: $80

- Total Upfront Investment: $16,000

-

Scenario B: The "MOQ Trap" Order (High MOQ)

- Manufacturer’s required order: 1,000 jackets

- Landed cost per jacket (maybe slightly lower due to scale): $75

- Total Upfront Investment: $75,000

For a new brand, the difference between a $16,000 investment and a $75,000 investment is the difference between life and death. That extra $59,000 is now locked up in boxes sitting in a warehouse. It’s money you can’t use to run Facebook ads, sponsor a podcast, or travel to a trade show.

But it gets worse. That inventory isn’t free to hold. You have to pay for:

- Storage: Warehouse space costs money, and it adds up every single month.

- Insurance: You need to insure your inventory against fire, theft, and damage.

- Logistics: Managing and shipping 1,000 units is far more complex than managing 200.

Your cash flow is crippled, and you’re now "inventory rich but cash poor"—a perilous position for any business.

2.2 The Brand Dilution Disaster: When Good Products Go on Sale

So, you have 1,000 jackets. You launch, and your initial sales are strong, but after a few months, you’ve sold 300 units. You still have 700 jackets sitting in your warehouse, and the next season is approaching. What do you do?

The temptation is to panic and put everything on a deep discount. A 50% off "clearance sale" might seem like a good way to liquidate stock and recoup some cash. But the long-term damage to your brand can be catastrophic.

When you position yourself as a premium, high-performance outdoor brand, your price is part of your story. It signals quality, innovation, and value. The moment you start offering deep discounts, you train your customers to wait for sales. They think, "Why should I pay $300 at launch when I can get it for $150 in six months?"

This erodes your perceived value and destroys your profit margins. You enter a vicious cycle: you over-ordered to meet an MOQ, you were forced to discount to move the excess inventory, you made very little profit, and now you don’t have enough capital to fund the next production run without taking on even more risk. This is how brands bleed out.

2.3 Innovation Paralysis: The Inability to Test and Learn

The modern market rewards agility. The ability to test a new idea, learn from the customer, and iterate quickly is a massive competitive advantage. High MOQs completely destroy this ability.

Imagine you have a brilliant, but unproven, idea for a niche product. Perhaps it’s an ultralight, highly specialized vest for upland bird hunters, or a technical layering system designed from the ground up for women, a market that has been historically underserved6. We explore the unique needs of this demographic in our Ultimate Guide to Women’s Hunting Clothes for 20257.

This is a fantastic idea! But is the market ready for it? How big is the demand? What features are most important?

The smart way to find out is to produce a small test batch of 150-200 units. You launch it to your most loyal customers, gather feedback, and see what happens. If it sells out instantly, you know you have a winner and can invest in a larger second run. If the feedback is that a pocket needs to be moved or the fit needs adjusting, you can make that change before scaling up.

High MOQs make this impossible. You can’t "test" an idea with a 1,000-piece order. You are forced to go all-in on an unproven concept. The financial risk is so immense that most brands in this position will simply kill the innovative idea before it even gets to the prototype stage. They stick to "safe" products. Their brand becomes stagnant. They lose their edge.

Innovation paralysis is the silent killer of brand momentum. It’s the unseen cost of the MOQ trap, and it prevents you from building the dynamic, customer-responsive brand you dream of.

2.4 The Supply Chain Black Hole

When you place a massive order, your entire business becomes singularly focused on that one product. Your time, energy, and capital are all tied up in that single SKU. If there is any disruption in the supply chain—a delay in fabric delivery, a problem at the port, a quality control issue8—your entire business grinds to a halt. You have no other products to sell, no other revenue streams to rely on. You have created a single point of failure that can be catastrophic.

Falling into the MOQ trap is not a simple miscalculation; it’s a strategic blunder that can unravel your entire business. It starves you of cash, devalues your brand, stifles your creativity, and makes you vulnerable to supply chain shocks. Avoiding this trap is the first and most critical battle for any emerging outdoor brand.

Chapter 3: The Strategic Toolkit – How to Navigate and Negotiate MOQs

Now that you understand the economics behind MOQs and the dangers of the trap, it’s time to shift from theory to action. This is the heart of our masterclass: the practical, real-world strategies you can employ to navigate the MOQ challenge. This isn’t about finding a magical factory with no minimums; those rarely produce the quality you need. This is about being smarter, more creative, and more collaborative than your competition.

This process is a core part of what we do as Your Expert Hunting Apparel Manufacturer & Development Partner9. We don’t just present problems; we build solutions.

3.1 Strategy 1: The Material & Component Master Plan

As we established, the primary driver of high MOQs is almost always raw materials. Therefore, your most powerful lever is a smart material and component strategy.

A) Leverage the Library: The Power of In-Stock Materials

The single fastest way to lower your MOQ is to utilize your manufacturer’s library of in-stock materials. A well-established partner like Hi-nect has deep relationships with mills and often holds stock of high-quality, proven fabrics that we use across multiple clients’ projects.

- What it is: Instead of developing a custom fabric from scratch, you select a material that the factory already has on hand or can easily order in smaller quantities from a mill’s "running line."

- Why it works: The mill’s large MOQ has already been met by the manufacturer. We can then allocate a smaller portion of that fabric (say, 300-500 meters) to your production run. This immediately drops your unit MOQ from the 1,000+ range down to a much more manageable 200-500 pieces.

- The Trade-off: The fabric won’t be 100% exclusive to your brand. Another brand might be using the same base material. However, you can still create a unique product through your design, fit, features, and branding.

- The Pro-Tip: I always advise new brands to launch their first collection using in-stock fabrics. It allows you to get to market quickly, test your designs, and build your cash flow. Once you have a proven seller, you can reinvest your profits into a custom fabric for version 2.0. This is a key principle in accelerating your entire development timeline, a topic we cover in-depth in our guide, From Prototype to Production10.

B) The Art of Consolidation

Think of your product line as a system. Instead of designing each piece in a vacuum, look for opportunities to consolidate components.

- The Scenario: You want to launch a small collection: a hardshell jacket, a softshell pant, and a fleece vest.

- The Wrong Way:

- Jacket: Custom "Pine Green" color, YKK Zipper in "Pine Green."

- Pants: Custom "Earth Brown" color, YKK Zipper in "Earth Brown."

- Vest: Custom "Slate Grey" color, YKK Zipper in "Slate Grey."

- Result: You now have to meet three separate fabric MOQs and three separate custom zipper MOQs. Your total unit requirement is massive.

- The Smart Way:

- Design all three pieces to work with a single, high-quality black YKK zipper package (main zips, pocket zips, etc.). Black is a stock color with a very low MOQ.

- Use the same woven main label and care label across all three styles.

- Use the same cord locks and shock cord on the jacket and pants.

- Result: By consolidating your trims, you can now place one larger, combined order for them, easily meeting the minimums. This allows the factory to focus the MOQ negotiation purely on the fabric, where you can then use the in-stock strategy.

C) The "Greige Goods" Gambit

This is a more advanced but powerful strategy. "Greige" (pronounced "gray") is raw, undyed fabric. Sometimes, a mill’s MOQ for weaving greige goods is lower than their MOQ for dyeing a custom color.

- How it works: Your manufacturer can sometimes commit to a larger run of greige fabric from a mill. They can then take this greige fabric to a smaller, more flexible dye house and dye it in smaller batches.

- The Benefit: This allows you to get a custom color without committing to the mill’s massive dye lot size. You might be able to get 500 meters of three different custom colors instead of being forced to buy 1,500 meters of one color.

- The Caveat: This requires a manufacturer with strong, sophisticated supply chain relationships and a willingness to take on the inventory risk of the greige goods. It’s a key indicator of a true partner.

3.2 Strategy 2: Design and Product Line Intelligence

How you structure your product offering can have a huge impact on your MOQs.

A) Maximize Your Colorways

The factory’s primary concern is the total number of units per style, as this relates to the setup efficiency of the sewing line. The fabric mill’s concern is the number of meters per color. You can use this to your advantage.

- The Scenario: The factory’s MOQ is 800 pieces per style. The fabric mill’s MOQ is 1,000 meters per color (which makes about 500 jackets).

- The Solution: Instead of launching two different jacket styles at 400 pieces each (which the factory would reject), you launch one jacket style in two different colorways.

- Color A: 500 pieces (uses 1,000m of fabric, meeting the mill’s MOQ).

- Color B: 500 pieces (uses 1,000m of fabric, meeting the mill’s MOQ).

- Total: 1,000 pieces of one style. This meets the factory’s sewing MOQ and the mill’s dyeing MOQ. You get product diversity without needing to develop a second style.

B) The Tiered Collection Approach

Don’t treat every product the same. Structure your line into tiers to manage risk and MOQs intelligently.

- Tier 1: The Core Collection. These are your bread-and-butter items. A simple, high-quality merino base layer or a logo hoodie. Design these using in-stock fabrics and consolidated trims for the lowest possible MOQs. These are your consistent revenue drivers.

- Tier 2: The Hero Product. This is your innovative, flagship jacket or pant. This is where you invest more capital and commit to a higher MOQ, because you’ve built the marketing story around it.

- Tier 3: The Limited Edition / Test Product. This is where you experiment. A unique camo pattern, a specialized piece for a niche market. Negotiate with your partner to produce a very small run (100-200 pieces), perhaps by paying a surcharge per unit to cover their inefficiency. The goal here isn’t profit; it’s market research.

3.3 Strategy 3: The Partnership Offensive

This is the most crucial strategy. You can’t execute any of the above without a manufacturing partner who is on your team. The relationship must be built on transparency, trust, and creative problem-solving.

A) Finding the Right Fit: Ask the Hard Questions

When you are vetting potential manufacturers, don’t just ask "What is your MOQ?". That’s a dead-end question. Instead, treat it like an interview. Our guide on How to Pick the Best Hunting Clothing Manufacturer11 offers a deep dive into this vetting process. Key questions to ask include:

- "We are a growing brand and managing MOQs is critical for us. Can you walk me through how you typically work with brands of our size to find solutions?"

- "Do you have a library of in-stock or running line fabrics you can share with us?"

- "What are your surcharges for producing below your standard MOQ, and what is the absolute lowest volume you would consider for a new partner?"

- "Can you share a story of another small brand you’ve helped scale successfully?"

Their answers will tell you everything you need to know. A factory that just repeats "Our MOQ is 1,000 pieces" is a transactional supplier. A partner who engages in a creative, problem-solving conversation is the one you want.

B) The Power of the Forecast

Be transparent with your potential partner about your long-term vision. Don’t just present an order for 200 pieces. Present a growth plan.

- The Pitch: "Here is our first order for 200 pieces of Style A. Our plan is to test the market with this run. Based on our projections, we plan to place a re-order for 500 pieces in six months, and we are already developing Style B, which we project will be a 700-piece order for next year. We are looking for a partner to go on this journey with us."

- Why it Works: This changes the entire dynamic. The factory is no longer looking at a single, unprofitable 200-piece order. They are looking at the potential of a long-term, high-growth account. They are now incentivized to invest in you, to be flexible on that initial order to win the larger future business.

C) Be Willing to Pay for Flexibility

Sometimes, the only way to get a low volume run is to pay for it. A factory might agree to a 200-piece run if you agree to pay a 15-25% surcharge on the unit price. While this hurts your initial margin, it can be a brilliant strategic investment.

- The Math: Paying an extra $15 per unit on 200 jackets costs you $3,000.

- The Alternative: Being forced to order 800 extra jackets at $75 each costs you $60,000 in capital and exposes you to all the risks of the MOQ trap.

Paying a small premium for the flexibility to test your market and protect your cash flow is one of the smartest investments a new brand can make.

Navigating MOQs is a strategic dance. It requires a deep understanding of the supply chain, a clever approach to design, and, above all, a collaborative and transparent relationship with your manufacturing partner. The goal is not to bully a factory into an unprofitable order; the goal is to co-create a solution that allows you to enter the market intelligently, setting the stage for a long and profitable partnership.

Chapter 4: The Hi-nect Partnership Model – Manufacturing Reimagined for Growth

Everything we’ve discussed—the strategies, the mindset, the collaborative approach—is not just theory. It is the core DNA of why Hi-nect exists. We founded our company not to be another faceless factory in the global supply chain, but to be the manufacturing launchpad that we saw so many ambitious brands desperately needed. Our entire process is built around solving the MOQ problem and empowering our partners to scale sustainably.

When you work with Hi-nect, you’re not just submitting a purchase order; you’re entering into a strategic development process.

The Onboarding & Discovery Phase

The first conversation we have with a new brand is never about price. It’s about vision.

- Who is your customer?

- What problem does your product solve?

- What is your unique place in the competitive landscape, among the brands listed in our Top 13 Hunting Apparel Manufacturers for 202512?

- What is your 1-year, 3-year, and 5-year plan?

This deep understanding allows us to move beyond a simple MOQ number and start acting as true consultants. We become an extension of your team, proactively identifying opportunities and risks.

A Culture of Creative Problem-Solving

When an MOQ issue arises, our response is not "no." Our response is "how?" Our team of merchandisers and sourcing specialists will immediately present a menu of options, much like the strategies outlined in Chapter 3.

- "We can’t get your custom ‘Coyote Brown’ fabric in a small run, but our partner mill has a fantastic, high-performance equivalent in their running line. It’s about 95% of the way there on color. We can get samples to you by Tuesday. This would allow you to produce 300 pieces instead of 1,500."

- "The custom cord lock you designed has a 10,000-piece MOQ. However, we have a stock component that is functionally identical and looks very similar. By using the stock part on your first run, you can save thousands in mold fees and meet a much lower minimum. We can tool your custom version for Season 2 once the product is proven."

- "Your total volume is low, but you are using the same pocket zipper on three different styles. If we group the purchase of that zipper for all three styles together, we can easily meet the supplier’s MOQ. This allows us to be more flexible on the individual style minimums."

This is the difference between a supplier and a partner. A supplier identifies problems. A partner delivers solutions.

A Shared-Risk Philosophy

We are not short-term thinkers. We know that if we are overly rigid and force a new brand into a risky inventory position, they might not be around to place a second order. That is a loss for everyone.

We view our flexibility on initial orders as a strategic investment in our partners’ future success. We are willing to absorb some of the initial inefficiency of a smaller run because we are building a relationship for the long term. We are betting on your vision, your passion, and our ability to help you execute it flawlessly. Our goal is to be the answer to the question every brand asks: What Company Makes The Best Hunting Clothes?13 The answer is the one with the best product, and the best product is born from the best manufacturing partnership.

Conclusion: MOQs are a Filter, Not a Wall

The Minimum Order Quantity is one of the most intimidating and misunderstood concepts in the apparel industry. For too long, it has acted as a gatekeeper, filtering out passionate entrepreneurs and innovative ideas simply because they couldn’t meet an arbitrary number on a spreadsheet.

But as we have seen in this masterclass, the MOQ is not an immovable wall. It is a complex, dynamic variable that can be understood, influenced, and strategically managed. It is a filter, yes, but it filters not for size, but for seriousness. It filters for brands who are willing to do the hard work of building a smart material strategy, designing an intelligent product line, and, most importantly, cultivating a true, collaborative partnership with their manufacturer.

The journey from a brilliant idea to a thriving brand is long and challenging. There will be obstacles at every turn. But the MOQ does not have to be the one that stops you. By armed with the knowledge in this guide, you can approach the manufacturing world not with fear, but with confidence. You can transform the conversation from "What is your MOQ?" to "How can we work together to build something incredible?"

That is the question that opens doors. That is the question that launches brands. And at Hi-nect, it’s the question we are always ready to answer.

References

[1] Understanding Minimum Order Quantity Clothing Manufacturers And How To Work With Them 1

[2] Minimum Order Quantities (MOQ) – Everything You Need To Know! 2

[3] All You Need to Know About Garment Costing and Pricing 3

[4] Understanding Injection Molding Cost for Manufacturers 4

[5] What is a tech pack and why you need one for apparel production 5

[6] The Rise Of Women In The Hunting World 6

[7] The Ultimate Guide to Women’s Hunting Clothes for 2025 7

[8] Our Commitment to Quality Control 8

[9] Your Expert Hunting Apparel Manufacturer & Development Partner 9

[10] From Prototype to Production: Accelerating Your Hunting Gear Development 10

[11] How to Pick the Best Hunting Clothing Manufacturer 11

[12] Top 13 Hunting Apparel Manufacturers for 2025 12

[13] What Company Makes The Best Hunting Clothes? 13

Ready to elevate your outdoor apparel line?

Let’s talk. We offer flexible MOQ, fast samples, and expert guidance — get your quote today.

You may also be interested in:

A Hunter's Guide to Waterproof & Breathable Fabric Science

Introduction For any serious hunter, the right apparel is not a luxury; it is a critical piece of equipment that

From Prototype to Production: Accelerating Your Hunting Gear Development

You’ve got a killer idea for a piece of hunting gear. A jacket that’s lighter, a pack that’s smarter, a

Top 13 Hunting Apparel Manufacturers 2025

I’ve been in the performance apparel industry for over 15 years, and let me tell you, choosing the right hunting