The Ultimate Guide to Women's Hunting Clothes for 2025

📌 Table of Contents

As the founder of Hi-nect, I have dedicated my career to the science and art of high-performance apparel. I’ve witnessed the evolution of materials from basic waterproof coatings to intelligent, breathable membranes, and I’ve seen manufacturing shift from a simple commodity to a critical strategic advantage. Today, no segment of the outdoor market better represents this evolution than women’s hunting apparel. For too long, this category was an afterthought. Now, it is a frontier of innovation. The trends for 2025 are clear: a profound focus on gender-specific ergonomics, advanced solutions for late-season warmth, a rapid shift towards sustainable, eco-friendly materials.

For the product development and sourcing directors tasked with navigating this dynamic landscape, the challenge is immense. You are not just creating garments; you are engineering systems that must provide safety, stealth, and comfort in the most demanding conditions, all while meeting the nuanced expectations of a discerning and rapidly growing consumer base. The selection of your manufacturing partner has never been more critical. This guide is my expert analysis of the key trends, technical requirements, and strategic considerations necessary to build a market-leading women’s hunting apparel line in 2025. It is designed to help you not only understand the market but to equip you with the knowledge to choose a partner who can transform your vision into a successful reality.

1. The Market Shift: Why Women’s Hunting Apparel is a Critical Growth Category

From my vantage point as both a manufacturer and an industry analyst, I see market shifts not just in spreadsheets, but in the very nature of the technical inquiries and development projects that cross my desk. Over the past five years, the most significant and sustained shift has been the explosive growth and increasing sophistication of the women’s hunting apparel category. This is not a fleeting trend; it is a fundamental and permanent realignment of the market, presenting one of the most significant growth opportunities for brands that are agile and insightful enough to seize it.

For decades, the industry’s approach to women’s hunting gear was, to be blunt, a strategic failure. The prevailing model was what we now derisively call "shrink it and pink it." Factories would take a men’s pattern, grade it down to smaller sizes without any anatomical reconsideration, and often apply a splash of pink or purple trim as a superficial nod to the female consumer. This approach was not just lazy; it was deeply flawed. It ignored the fundamental ergonomic differences between male and female bodies, resulting in gear that was uncomfortable, ill-fitting, and functionally compromised. A jacket that is too broad in the shoulders and too tight in the hips restricts movement. Pants with a rise designed for a male torso chafe and bunch. A backpack engineered for a male frame fails to distribute weight correctly on female hips, leading to fatigue and pain. The result was a generation of female hunters who were underserved, forced to make do with inadequate equipment that hindered their performance and enjoyment of the sport.

This historical inadequacy has created a massive, pent-up demand for authentic, purpose-built women’s gear. Today’s female hunter is more knowledgeable, more demanding, and more vocal than ever before. She is an expert in her own right, deeply invested in the sport and unwilling to accept substandard equipment. She researches materials, understands layering systems, and values gear that is meticulously designed for her body and her specific hunting style. This demographic shift represents a powerful commercial opportunity. Brands that continue to offer repurposed men’s gear will be left behind, while those who invest in genuine, ground-up women’s design will capture market share and build fierce brand loyalty.

The strategic imperative for product directors and sourcing managers is clear: you must treat the women’s line not as an accessory to the men’s collection, but as a core, standalone category deserving of its own dedicated research, design, and development resources. This requires a new way of thinking and, critically, a new kind of manufacturing partnership. The "shrink it and pink it" model was enabled by traditional, high-volume factories that were happy to take a simple pattern and produce it cheaply at scale. They were not equipped, nor were they incentivized, to engage in the complex process of developing and refining anatomically correct women’s patterns.

To succeed in 2025, brands need a partner who understands the nuances of female ergonomics. They need a partner with a sophisticated R&D department that can collaborate on fit, prototyping, and testing. They need a partner with flexible production capabilities who can handle the potentially smaller initial volumes of a niche line without imposing prohibitive Minimum Order Quantities (MOQs). The brands that will win in this space are the ones who recognize that building a successful women’s line begins with choosing a manufacturing partner who is as committed to getting the details right as they are. This is no longer about simply sewing fabric together; it is about engineering performance for a new and powerful generation of hunters.

2. The 2025 Trend Forecast: Key Drivers Shaping Product Development

To develop a winning women’s hunting line for 2025, one must look beyond the current market and anticipate the forces that will shape consumer expectations tomorrow. My team at Hi-nect and I dedicate a significant portion of our resources to this kind of analysis—attending trade shows like ISPO and Performance Days, deconstructing competitor garments, and maintaining a constant dialogue with material innovators. From this research, four dominant trends have emerged that will define the next generation of women’s hunting apparel.

Trend 1: The Ascendancy of Gender-Specific Ergonomics

The single most important trend is the move away from unisex or poorly adapted men’s designs toward true, gender-specific ergonomics. This goes far beyond simple sizing adjustments. It is a holistic approach to design that considers the unique biomechanics and anatomy of the female body to enhance comfort, mobility, and overall performance in the field.

- Anatomical Patterning: The foundation of ergonomic design is the pattern itself. For women, this means accounting for a wider hip-to-waist ratio, a different shoulder width, and chest dimensions. A properly designed women’s jacket will incorporate darts or princess seams to create shape through the torso, preventing the boxy, restrictive fit of a men’s garment. Pants must feature a properly calibrated rise (the distance from the crotch to the waistband) and a contoured waistband that sits securely on the hips without gapping at the back. At Hi-nect, our pattern-makers work with 3D modeling software to visualize fit on a female avatar before a single piece of fabric is cut, allowing us to refine these crucial details digitally.

- Articulated Joints for Unrestricted Movement: Hunting requires dynamic movement—climbing, crouching, drawing a bow, or shouldering a firearm. Articulation involves building extra shape and volume into key joint areas like the elbows and knees. For women’s gear, this must be done in concert with the anatomical patterning to ensure the articulation points align correctly with the wearer’s body, preventing binding and fabric pull.

- Intelligent Feature Placement: Ergonomics also dictates the placement of every feature. Pockets on a jacket must be positioned to remain accessible even when wearing a backpack with a hip belt, which sits differently on a woman’s torso. The placement of ventilation zippers (pit zips) needs to be optimized for easy access and effectiveness. Even the length of a jacket’s hem is an ergonomic consideration, needing to provide coverage without impeding the leg movement required for climbing steep terrain.

- The Manufacturing Implication: Executing true gender-specific ergonomics is a complex manufacturing challenge. It requires a partner with a sophisticated pattern-making and prototyping capability. It is an iterative process of creating a sample, fitting it on a real person, making micro-adjustments, and repeating the cycle until the fit is perfect. This is simply not possible with a factory geared only for mass production. It demands a partner with an R&D-centric mindset who sees themselves as a co-developer of the product, not just an order-taker.

Trend 2: Advanced Thermal Management and Systems-Based Warmth

The 2025 trend forecast shows a clear emphasis on solutions for late-season warmth. For women’s apparel, this is particularly critical, as physiological differences can affect thermal regulation. The market is moving beyond single, bulky garments toward intelligent, systems-based approaches that allow the hunter to adapt to changing conditions and activity levels. This is a core area of technical expertise.

- Sophisticated Layering Systems: The most effective approach to warmth is a three-part system: a moisture-wicking base layer, an insulating mid-layer, and a protective outer shell. For a women’s line, each layer must be designed to work in concert, with a streamlined fit that avoids bulk. The manufacturing challenge is to maintain consistent sizing and fit across all three layers, ensuring they integrate seamlessly.

- Innovation in Insulation: The choice of insulation is paramount.

- Down: Offers the best warmth-to-weight ratio and is highly compressible. However, it loses its insulating properties when wet. Hydrophobic down (treated with a water-repellent coating) is a key technology to specify.

- Synthetic Insulation: Materials like PrimaLoft® or Thinsulate™ retain warmth even when damp and are generally more durable and affordable than down. The trend is toward continuous filament insulations that are softer, more packable, and mimic the feel of down.

- Active Insulation: Newer technologies like Polartec® Alpha® are designed to be highly breathable, dumping excess heat during high-exertion periods. This is ideal for active hunting styles and prevents the "sweat-freeze" cycle.

- Heated Apparel: The integration of heated elements is moving from a niche feature to a mainstream expectation for premium cold-weather gear. These systems use thin, flexible carbon fiber elements powered by a rechargeable battery pack to provide active warmth. For women’s gear, the placement of these heating zones (e.g., core, lower back, hands) is a critical design consideration. Sourcing reliable, safe, and durable heating systems is a key supply chain challenge that requires a manufacturer with experience in electronics integration.

- The Manufacturing Implication: Building effective thermal systems requires deep material knowledge and advanced construction capabilities. A manufacturer must have experience sourcing a wide range of insulations and the expertise to construct garments with complex baffle systems (for down) or quilt patterns (for synthetics) that prevent cold spots. For heated gear, the partner must have established quality control processes for handling electronic components, ensuring both performance and safety.

Trend 3: The Convergence of Performance and Sustainability

The modern consumer, including the female hunter, is increasingly conscious of the environmental impact of her purchases. The 2025 trend shows a definitive shift toward eco-friendly materials that do not compromise on technical performance. Brands that successfully integrate sustainability into their story will have a powerful competitive advantage.

- Recycled Materials: The most significant sustainable trend is the use of recycled polyester and nylon. These fabrics are derived from post-consumer waste (like plastic bottles) and have a significantly lower carbon footprint than their virgin counterparts. High-performance recycled fabrics are now available that match the durability, water-resistance, and feel of virgin materials. The key is to partner with a manufacturer who has access to certified recycled material suppliers (e.g., GRS – Global Recycled Standard).

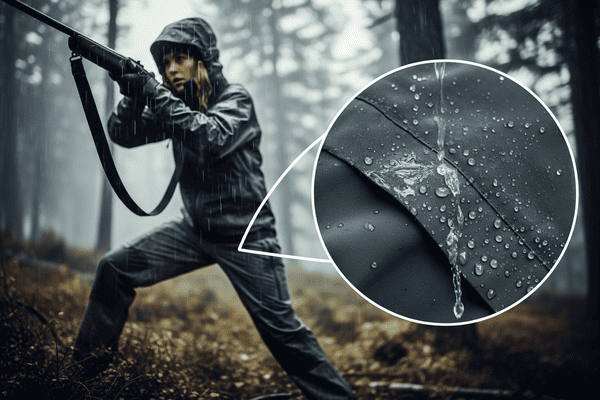

- PFC-Free DWR: Durable Water Repellent (DWR) is the chemical finish applied to the outside of garments to make water bead up and roll off. For years, these finishes were based on perfluorinated chemicals (PFCs or PFAS), which are now known to be persistent environmental pollutants. The industry is rapidly transitioning to PFC-free DWR alternatives. While early versions were less durable, the latest C0 (zero carbon) DWR technologies offer excellent performance and longevity. A forward-looking manufacturer should already be an expert in sourcing and applying these new finishes.

- Natural and Bio-Based Fibers: While synthetics dominate outerwear, natural fibers like Merino wool remain a top choice for base layers due to their natural thermoregulation and odor resistance. Brands are also exploring innovative bio-based materials, such as plastics derived from corn or castor beans, as a renewable alternative to petroleum-based synthetics.

- Ethical Production: Sustainability extends beyond materials to the manufacturing process itself. This includes certifications like bluesign®, which ensures responsible chemical use, and BSCI (Business Social Compliance Initiative), which audits for fair labor practices.

- The Manufacturing Implication: Navigating the world of sustainable materials and certifications is complex. Brands need a partner who is not just willing but proactive in this area. A good partner will have an established network of certified sustainable suppliers, a deep understanding of the performance trade-offs of different eco-materials, and the documentation to back up any environmental claims. This transparency is essential for building trust with the end consumer.

Trend 4: The Fusion of Function and Aesthetics

While performance remains paramount, the 2025 female hunter also expects her gear to look good. The trend is a move toward a more sophisticated aesthetic that combines rugged functionality with considered design elements, recognizing that style and performance are not mutually exclusive.

- Modern Silhouettes: The bulky, shapeless garments of the past are being replaced by more tailored, athletic silhouettes. This is a direct result of the focus on gender-specific patterning. The goal is a fit that is flattering without being restrictive, providing a clean and capable look.

- Sophisticated Color Palettes: While camouflage is essential, brands are expanding their color palettes for solid pieces (like mid-layers and vests) beyond traditional earth tones. This includes muted, nature-inspired colors that are both functional in the field and stylish enough for casual wear. This crossover appeal significantly increases the value proposition of a garment.

- Advanced Camouflage Patterns: Camouflage itself is becoming more sophisticated. Brands are moving beyond simple mimicry patterns toward scientifically designed concealment systems (like Sitka’s Optifade or KUIU’s Valo). For women’s lines, there is also an opportunity to develop unique patterns or colorways that provide a distinct brand identity while remaining highly effective.

- Attention to Detail: The perception of quality and style often comes down to the details. This includes the choice of trims—using sleek, low-profile zippers, custom-molded cord pulls, and subtle, well-placed logos. Even the texture and hand-feel of the fabric contribute to the overall aesthetic appeal.

- The Manufacturing Implication: Achieving a high-end aesthetic requires a manufacturer with an eye for detail and a commitment to craftsmanship. It means precise stitching, clean finishing, and the ability to source a wide variety of high-quality trims and hardware. The partner must understand that the "look and feel" of the garment are just as important as its technical performance specifications and must have quality control processes in place to ensure aesthetic consistency across the entire production run.

3. Building the Ultimate Women’s Hunting System: A Layer-by-Layer Breakdown

Engineering a successful women’s hunting apparel line is about creating a cohesive system, where each piece is individually excellent but becomes even more effective when used in concert with the others. As a manufacturer, this is where our deep technical expertise comes to the forefront. Here is my layer-by-layer breakdown of what it takes to build a market-leading system for 2025.

Base Layers: The Foundation of Performance

The base layer is the most intimate part of the system, sitting directly against the skin. Its primary job is moisture management—moving perspiration away from the body to keep the wearer dry and prevent chilling. For women’s hunting, comfort, fit, and odor control are also paramount.

- Material Selection:

- Merino Wool: This natural fiber is the gold standard for many. It is exceptionally soft, breathes well, provides warmth even when damp, and is naturally odor-resistant. The key specification is the fiber diameter, measured in microns (e.g., 17.5 to 19.5 microns for next-to-skin softness) and fabric weight (e.g., 150-250 g/m²).

- Treated Synthetics: Polyester and polypropylene are excellent at wicking moisture and are very durable. Their main drawback is a tendency to retain odor. The solution is to specify fabrics treated with an antimicrobial technology, such as Polygiene® or silver-based treatments, which inhibit the growth of odor-causing bacteria.

- Construction and Fit:

- Flatlock Seams: To prevent chafing, all seams on a base layer must be flatlock stitched. This creates a flat, smooth seam that won’t irritate the skin under the pressure of a pack.

- Ergonomic Paneling: A well-designed base layer will use different fabric weights or knit structures in different body zones (body mapping). For example, a more open knit might be used in high-sweat areas like the underarms and back, while a tighter knit is used in the core for warmth.

- Women-Specific Fit: This includes a contoured torso, sufficient length to stay tucked in, and thumbholes to keep sleeves in place when adding layers.

- Manufacturing Considerations: Producing high-quality base layers requires expertise in handling fine-gauge knit fabrics and specialized machinery for flatlock stitching. Sourcing high-quality Merino wool or certified treated synthetics is a critical first step where a partner’s supply chain is invaluable.

Mid-Layers: The Engine of Insulation

The mid-layer’s role is to trap body heat, providing the bulk of the system’s insulation. The key is versatility—it should be warm but also breathable and packable, allowing the hunter to add or remove it as conditions change.

- Material Selection:

- Fleece: A classic choice, fleece (like Polartec®) is warm, breathable, and quick-drying. Grid fleece is a popular variation that features a grid pattern of channels on the inside face, which enhances breathability and reduces weight.

- Down Insulation: For maximum warmth with minimum weight, down-insulated vests and jackets are ideal. Key specs are fill power (e.g., 800-fill-power indicates high loft and quality) and the use of hydrophobic down.

- Synthetic Sheet Insulation: Materials like PrimaLoft® Gold are engineered to provide high levels of warmth, water resistance, and compressibility. They are an excellent choice for damp conditions.

- Construction and Fit:

- Streamlined Design: A mid-layer should have a trim, athletic fit to layer cleanly under an outer shell without creating bulk.

- Technical Features: Useful features include a soft, brushed chin guard over the main zipper, zippered handwarmer pockets, and a simple elastic or drawcord hem to seal out drafts.

- Hybrid Construction: A popular trend is to use hybrid designs that map different materials to different areas. For example, a vest might have an insulated core for warmth with stretch fleece side panels for enhanced mobility and breathability.

- Manufacturing Considerations: Building high-quality insulated garments is a technical skill. For down, it requires specialized machinery for blowing the down into individual baffles and ensuring even distribution. The baffle construction itself (sewn-through vs. box baffle) is a key technical decision. For synthetic insulation, precise cutting and quilting are necessary to ensure consistent performance.

Outerwear (Jackets & Pants): The Shield Against the Elements

The outer shell is the hunter’s primary defense against wind, rain, and snow. This is the most technically complex layer, where material science and construction quality are non-negotiable.

- The Holy Trinity: Waterproof, Windproof, Breathable:

- Waterproof Rating: Measured in millimeters (mm), this indicates the amount of water pressure a fabric can withstand before leaking (e.g., 10,000mm is good, 20,000mm is excellent for harsh conditions).

- Breathability Rating: Measured in grams (g/m²/24hr), this indicates how much water vapor can pass through the fabric in a 24-hour period (e.g., 10,000g is good, 20,000g is excellent for high-exertion activities).

- Fabric Construction: This is typically a 2-layer, 2.5-layer, or 3-layer laminated fabric. A 3-layer (3L) construction, where the membrane is bonded between an outer face fabric and an inner backer, offers the most durability and is the standard for premium hunting gear.

- Durability and Stealth:

- Face Fabric: The outer fabric must be both durable and quiet. A brushed polyester or a specialized stretch-woven fabric is often used to reduce the noise of movement. The fabric’s denier (a measure of fiber thickness) indicates its durability.

- Reinforcements: High-wear areas like the shoulders, elbows, and seat should be reinforced with a more robust fabric, like Cordura®, to withstand abrasion from packs and terrain.

- Ergonomic and Functional Features for Women:

- Adjustable Hood: A well-designed hood should have multiple adjustment points (volume and aperture) to provide a snug fit over a beanie or cap without obscuring peripheral vision.

- Pocketing: Pockets must be strategically placed for access when wearing a pack. Handwarmer pockets should be fleece-lined. Secure internal pockets are essential for valuables.

- Ventilation: Long pit zips on jackets and outer thigh zips on pants are critical for dumping heat during strenuous activity.

- Articulated Fit: As mentioned in the trends, articulated elbows and knees are essential. For pants, a gusseted crotch provides a full range of motion.

- Women-Specific Pant Features: A key feature for women’s hunting pants is a "drop-seat" or side-zip design that allows for easier bathroom breaks in the field without having to remove all upper layers. This is a highly valued feature that demonstrates a deep understanding of the female hunter’s needs.

- Manufacturing Considerations: This is the pinnacle of technical apparel manufacturing. It requires a factory with a climate-controlled cleanroom for seam sealing, specialized machinery for taping and welding, and highly skilled operators. Every single seam on a waterproof garment must be sealed with waterproof tape, a process that requires precise temperature, pressure, and speed settings that vary depending on the fabric. Quality control must be rigorous, including hydrostatic head testing of the fabric and water-pressure testing of finished garments to ensure 100% waterproof integrity. This is the expertise that separates a true technical partner from a standard apparel factory.

4. Essential Accessories: The Details that Define the Hunt

While the layering system forms the core of a hunter’s apparel, a well-curated set of accessories is what elevates the system from good to great. For a women’s line, applying the same principles of gender-specific design to accessories is a critical differentiator. These items are not afterthoughts; they are essential pieces of gear.

Backpacks

A hunting pack is more than just storage; it is a critical piece of equipment that must carry gear comfortably and quietly for miles. For women, fit is everything.

- Gender-Specific Design: A woman’s pack needs a shorter torso length, a narrower shoulder harness, and S-curved shoulder straps that contour around the chest. Most importantly, the hip belt must be angled and padded to sit properly on a woman’s iliac crest, ensuring the load is transferred to the hips, not the shoulders.

- Key Features: Look for a frame system that balances support with flexibility, quiet materials and hardware, and logical pocket organization. A built-in rifle or bow carrying system is a key feature for many hunting styles.

- Manufacturing Implication: Building high-quality technical packs is a specialized skill involving complex bar-tacking for strength, multi-density foam lamination for comfort, and durable frame construction.

Boots

A hunter’s boots are their connection to the ground. Poorly fitting boots can end a hunt prematurely. All-day support and protection are non-negotiable.

- Women-Specific Lasts: Boots must be built on a women-specific last (the 3D model a boot is constructed around), which is typically narrower in the heel and wider in the forefoot than a man’s last. This ensures a secure fit and prevents blisters.

- Key Features: The choice of boot depends on the terrain and temperature. Look for a waterproof/breathable membrane (like GORE-TEX), an appropriate level of insulation (e.g., 400g-800g Thinsulate for cold weather), and a durable outsole with an aggressive lug pattern for traction.

- Sourcing Implication: While most apparel manufacturers don’t produce footwear, a good sourcing partner can help a brand connect with specialized, high-quality footwear factories that understand the nuances of women’s fit.

Gloves

Gloves present the classic challenge of balancing warmth with dexterity. A hunter needs to stay warm but also be able to operate their equipment.

- System Approach: The best solution is often a glove system: a thin, merino or synthetic liner glove for dexterity, paired with a heavily insulated, waterproof outer mitten or glove that can be removed for fine-motor tasks.

- Key Features: Look for pre-curved fingers for an anatomical fit, a leather or synthetic palm for grip, and a long gauntlet to seal out snow and drafts. For bowhunters, a glove or mitten with a fold-back trigger finger is essential.

- Manufacturing Implication: Glove construction is intricate and requires skilled operators. Creating a truly waterproof glove involves inserting a waterproof/breathable membrane "insert" or "bladder," a highly technical process.

Headwear & Gaiters

Controlling heat loss from the head is critical for thermal regulation.

- Headwear: A warm, windproof beanie is a staple. A balaclava or neck gaiter (like those from Buff®) offers versatile protection for the face and neck. A wide-brimmed hat is also useful for sun and rain protection in milder conditions.

- Gaiters: These are essential for keeping snow, debris, and water out of your boots. Look for a durable, waterproof fabric and a secure, adjustable fit that seals tightly around the boot and calf.

5. The Manufacturing Partnership: The Secret to a Successful Women’s Line

We have explored the market dynamics, the key trends, and the technical details required to build a market-leading women’s hunting apparel line for 2025. Now we must address the most critical component in bringing this vision to life: your manufacturing partner. The success or failure of your women’s line will be determined not just by your designers, but by the capabilities, flexibility, and expertise of the factory you choose.

The complexity we’ve outlined—the nuanced ergonomic patterning, the advanced thermal systems, the sustainable material sourcing, the intricate construction of waterproof outerwear—presents a series of challenges that the traditional factory model is fundamentally ill-equipped to handle. A conventional, high-volume factory is an execution machine. It is optimized for producing thousands of identical, simple garments at the lowest possible cost. Their model is based on rigidity and repetition, not agility and co-creation.

When a brand approaches such a factory with a technically complex, anatomically nuanced women’s jacket project, several points of failure immediately emerge:

- The "Fit" Problem: They lack the dedicated R&D and expert pattern-makers to engage in the iterative process of perfecting a women’s fit. They will default to simplifying the pattern, losing the ergonomic details that are the very foundation of a great product.

- The "MOQ" Barrier: Their business model requires high-volume orders to be profitable. They will impose a Minimum Order Quantity of thousands of units, making it financially impossible for a brand to launch a specialized women’s line or test new concepts. Innovation is stifled before it can even begin.

- The "Sourcing" Limitation: Their material library is typically limited to standard, low-cost options. They lack the sophisticated supply chain and expertise to source the latest sustainable materials, certified performance fabrics, or high-end technical trims that a premium line demands.

- The "Expertise" Gap: They may know how to sew, but they lack the deep, specialized engineering knowledge required for things like seam sealing, baffle construction, or electronics integration. They are generalists in a field that demands specialists.

This is precisely why I founded Hi-nect. I built this company to be the solution to these problems, to be the new model of manufacturing partner that ambitious, innovation-driven brands need to succeed. Our entire operation is structured to be an extension of your brand’s development team.

- We are R&D-Driven Specialists: Hi-nect was born from an R&D studio. Our DNA is in problem-solving and co-creation. We have a dedicated team of expert pattern-makers and technicians who live and breathe technical apparel. We thrive on the challenge of perfecting a women’s-specific fit and will work with you through as many prototype iterations as it takes to get it right.

- We Embrace Low MOQs: We believe innovation should be accessible. Our flexible production lines are engineered for efficiency even at smaller volumes. We welcome projects with MOQs as low as 50-100 units, empowering you to launch your women’s line, test new ideas, and serve your customers without prohibitive financial risk.

- We are Sourcing Experts: We have a dedicated global sourcing team and deep relationships with the world’s leading technical fabric mills and trim suppliers. Whether you need GRS-certified recycled polyester, the latest PFC-free DWR finish, or a specific type of PrimaLoft® insulation, we know where to find it and how to work with it.

- We Guarantee Technical Execution: We have invested in the specialized machinery and skilled operators required for the most complex constructions. Our seam sealing is meticulous, our insulation application is precise, and our quality control is uncompromising, backed by third-party testing reports for every shipment.

Choosing to build a women’s hunting line is a strategic decision to pursue a significant market opportunity. The next, and most important, decision is choosing a partner who has the specific expertise and collaborative mindset to help you win in that market.

Conclusion

The journey to creating a successful women’s hunting apparel line is one of the most exciting and rewarding endeavors in the outdoor industry today. It is a chance to connect with a passionate, knowledgeable, and loyal consumer base that has long been underserved. As we’ve seen, success in 2025 is not about compromise. It’s about delivering on every front: a truly ergonomic, gender-specific fit; an intelligent, systems-based approach to thermal management; a commitment to sustainable materials and ethical production; and a sophisticated aesthetic that blends performance with style.

This is a high bar to clear, and it cannot be done with an outdated, transactional approach to manufacturing. The brands that will lead this category will be those that forge deep, collaborative, and strategic partnerships. As someone who is deeply involved in this process every day at Hi-nect, my advice is to seek a partner who sees your vision, understands your challenges, and invests in your success as if it were their own. You need more than a factory; you need a dedicated technical team, a flexible production solution, and a proactive partner in innovation. We built Hi-nect to be that partner.

If you are ready to build a women’s product line that truly resonates with the modern huntress and leads the market rather than follows it, then Hi-nect is ready to collaborate. Visit our website or contact our team directly to discuss how we can engineer your most ambitious vision into a tangible, successful reality. Let’s connect with possibilities.

Contact us today!

Ready to elevate your outdoor apparel line?

Let’s talk. We offer flexible MOQ, fast samples, and expert guidance — get your quote today.

You may also be interested in:

A Hunter's Guide to Waterproof & Breathable Fabric Science

Introduction For any serious hunter, the right apparel is not a luxury; it is a critical piece of equipment that

Lowering MOQs: A Guide for Hunting & Outdoor Brands

You’ve done it. After countless late nights, sketches on napkins, and heated debates over fabric textures, you’ve perfected the design

From Prototype to Production: Accelerating Your Hunting Gear Development

You’ve got a killer idea for a piece of hunting gear. A jacket that’s lighter, a pack that’s smarter, a